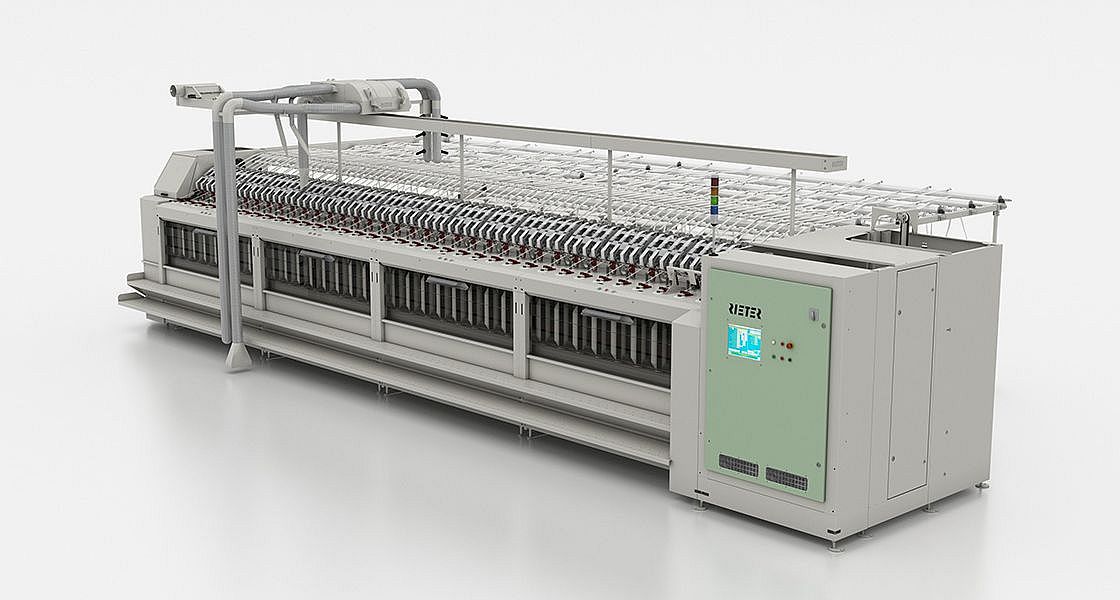

Product Details

The new generation of roving frames produces first-class rovings for minimal investment costs. The doffer of the roving frame F 40 provides a high level of machine efficiency thanks to a doffing time of only 1.5 minutes. With 252 spinning positions, it is ideally suited to long ring spinning machines. The preassembled sections enable rapid commissioning of the machine. The unique gear mechanism ensures precise bobbin build-up. A special designed spindle crown guarantees that roving tubes click into place, which in turn ensures the good running performance of the bobbins.