Boosting Productivity and Reducing Conversion Costs with a Blowroom Upgrade

Xiang Hengjia, Equipment Manager of Zhejiang Jiushun Textile Co., Ltd.

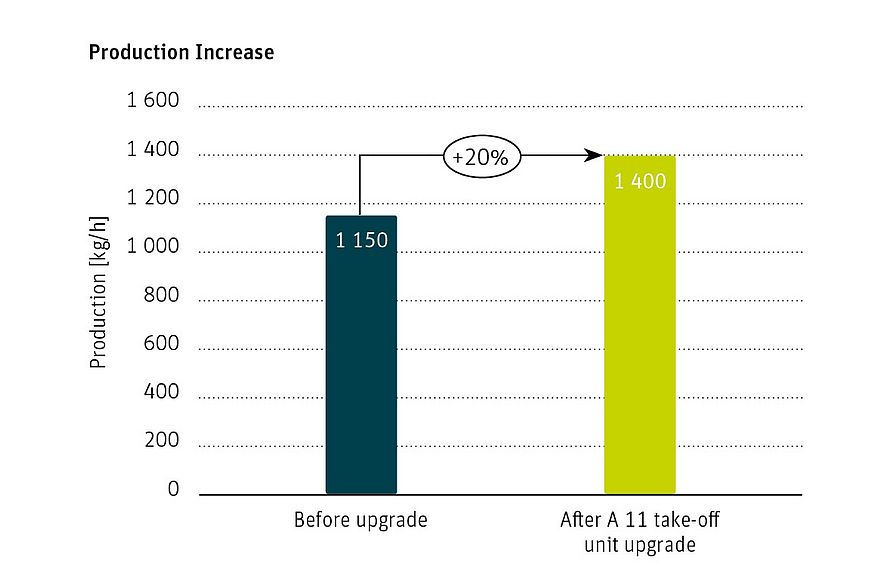

Zhejiang Jiushun Textile Co., Ltd. is a leading producer of rotor yarn for the Chinese textile market. To strengthen its market leadership, Zhejiang aimed to increase its productivity, thereby reducing the conversion cost. After visiting the customer’s spinning mill, the Rieter after sales team identified productivity leverage in the blowroom. By upgrading the bale opener with an A 11 take-off unit, the production output has increased by 20% while reducing conversion costs.

Zhejiang Jiushun Textile Co., Ltd. produces 100% cotton yarn or Lyocell/cotton blended yarn from Ne 7 to Ne 40 with Rieter machines. The company has always invested in Rieter technology and products due to the consistent performance and high quality. The mill today is equipped with different generations of Rieter cards, draw frames and rotor spinning machines. Recently, the customer invested in Rieter’s new generation machines like card C 80, draw frame RSB-D 50 and semi-automated rotor spinning machine R 37 including ROBOdoff, the automated package change robot.

The Challenge

Zhejiang Jiushun Textile Co., Ltd. wanted to strengthen its market leadership and decided to add production capacity to increase its yarn production output. The new machines will help increase productivity, lower production costs and enhance flexibility in the process so that the company can respond faster to market requirements. The customer wanted to keep the existing blowroom line but needed a solution to increase the productivity of the fiber preparation machines. This would help maintain the production level with the newly added machines.

The Solution

The Rieter after sales team visited the customer’s spinning mill and identified productivity leverage in the blowroom. They installed an A 11 take-off unit upgrade which resulted in greater output and ensured a uniform feeding of the newly installed cards. The take-off unit upgrade is designed for optimized air flow by eliminating certain parts that affect the smooth transfer of the tuft. This enables a higher production output of up to 1 400 kg/h. The upgrade includes a new take-off arm that is simpler, has fewer components and offers a smaller driving unit for power saving. The upgrade also contains Metal-X, the strongest permanent magnet attachment available on the market at the grid of the take-off unit designed with several neodymium magnets that collect the iron parts in the bale. This lowers the risk of fire hazards in the blowroom line and thus ensures a safe working environment.

The Customer's Benefits

The solution helped the customer reach the desired production level. Not only does the upgraded A 11 take-off unit increase production output by 20%, from 1 150 kg/h to now 1 400 kg/h. It also saves 20% energy and reduces maintenance costs. In addition, the lifetime of the blowroom machine has been extended, and the risk of a fire accident was reduced. Most importantly, the after sales solution increases the mill’s overall productivity. The overall reduction in conversion costs for yarn production enabled Zhejiang Jiushun Textile Co. to defend their strong market position.

The new take-off arm upgrade helps us increase the yarn production by 20%, which positively impacts our overall output and increases our revenue significantly.Xiang Hengjia, Equipment Manager of Zhejiang Jiushun Textile Co., Ltd.

About Zhejiang Jiushun Textile Co., Ltd.

Zhejiang Jiushun Textile Co., Ltd. located in Lanxicity, Zhejiang province, China, was founded in 2010. The spinning mill focuses on producing and processing 100% cotton yarn or Lyocell/cotton blended yarn from Ne 7 to Ne 40. It has a total of 8 380 rotor spinning units with a production capacity of 75 tons per day which is sold to the Chinese market.