Economical Processing of Recycled Cotton Fibers with R 37

Liang Shixiao, Vice general manager of Wenzhou Mingshuo Industry Co. Ltd.

In the heart of Zhejiang province, Wenzhou Mingshuo Industry Co. Ltd. has become a leader in spinning recycled rotor yarn – mainly from fibers gained from selvedges and fabric waste. Specializing in Ne 6 to 16 recycled cotton yarn with 70% to 95% recycled content, Mingshuo’s success lies in the power of the Rieter semi-automated rotor spinning machines R 37. With five of these machines, Mingshuo spins Ne 16 blended yarns made from 95% recycled cotton and 5% viscose, which are then sustainably processed into denim. Mingshuo’s story is defined by innovation and eco-conscious excellence.

The Challenge

Wenzhou Mingshuo Industry Co. Ltd. faces the typical challenges in processing recycled fibers. The complexity arises from diverse sources of recycled raw materials, which leads to variations in composition, color, and fabric structure with each batch. Even though the market is demanding superior fabric appearance, the exact properties of recycled raw material are not predictable. The challenge is to find correct settings to remove not spinnable and disturbing contents in the materials.

In addition, Mingshuo is confronted with high electricity prices. This increases the pressure to reduce energy costs to control yarn conversion costs. The balance between cost control and quality improvement is crucial for Mingshuo as it strives to exceed the expectations of downstream customers in a demanding market.

The Solution

Rieter’s rotor spinning machine R 37 offers benefits that bring recycled yarn production to new heights. Equipped with an innovative spinning box, which features sensitive fiber opening and the ability to selectively extract disturbing content, the R 37 is able to process a broader spectrum of raw materials with highly effective impurity removal.

The advanced spinning box not only handles recycled raw materials with finesse but also achieves a better CV% and remarkable reduction in IPI, ensuring a smoother yarn production process. The R 37’s spinning box guarantees a smooth flow of fibers, to preserve valuable long fibers and to result in better fiber yield and yarns with high strength. In terms of energy efficiency, the R 37 leads the way with a highly efficient main drive and suction system. This intelligent design allows to minimize energy consumption.

The Customer’s Benefits

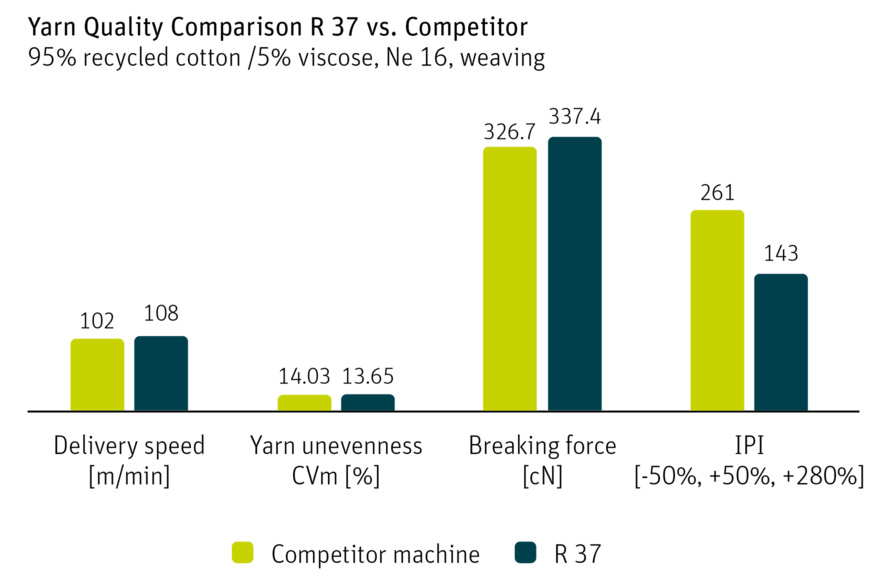

The R 37 provides benefits to Wenzhou Mingshuo Industry Co. Ltd. which set it apart from the competition. As the company also has rotor spinning machines from a competitor brand, it can make a direct comparison. Mingzhou observed advantages in output, quality, and energy efficiency compared to the latest competitor’s machine:

- Higher output: With the R 37 a remarkable 6% increase in yarn productivity is achieved. Thanks to a higher rotor speed, Mingshou achieves a better yarn strength and a higher overall output.

- Improved yarn quality: The unique spinning box of the R 37 with its optimized extraction of disturbing particles and optimized fiber flow, a 45% reduction in yarn imperfections is achieved. This also ensures a more consistent and high-quality end product.

- Energy savings: At Mingshou, the R 37 with its highly efficient drive and suction system saves energy of up to 15% compared to the competitor machines in the mill. This substantially contributes to cost-effectiveness.

- Weaving excellence: The yarn produced on the R 37 at Mingshuo proves popular in downstream in the weaving process due to its high strength and minimal hairiness. This results in high efficiency in warping and weaving. It also contributes to Mingshuo’s commitment to delivering products that meet and exceed the expectations of their customers.

The R 37 stands as an exemplar of stability and seamlessly combines high productivity with high delivery speeds, resulting in high output. With the precision of the R 37, we produce recycling yarns of superior quality, boasting exceptional yarn evenness, high strength, and minimal imperfections. Its remarkable performance results in minimal warp breaks in the weaving process – and finally in a clear fabric appearance. Compared to alternative options, yarns produced with the R 37 dominate the market and enjoy a preference that eliminates any excess stock.Liang Shixiao, Vice general manager of Wenzhou Mingshuo Industry Co. Ltd.

Download

About Wenzhou Mingshuo

Wenzhou Mingshuo Industry Co. Ltd. is located in Zheijiang province in China and produces rotor yarn, mainly from fibers gained from selvedges and fabric waste. Mingshuo specializes in spinning Ne 6-16 recycled cotton yarn with 70% to 95% recycled content and 5% viscose, which are then utilize in denim production. Its sustainable attitude in spinning underlines recent trend of textile industry.

Wenzhou Mingshuo Industrial Co. Ltd.

Longgang City

325810 Wenzhou City

China