Improving Yarn Quality and Efficiency with ESSENTIALmonitor

Anastasios Polychronos, Mill Manager of Nafpaktos Textile Industry S.A.

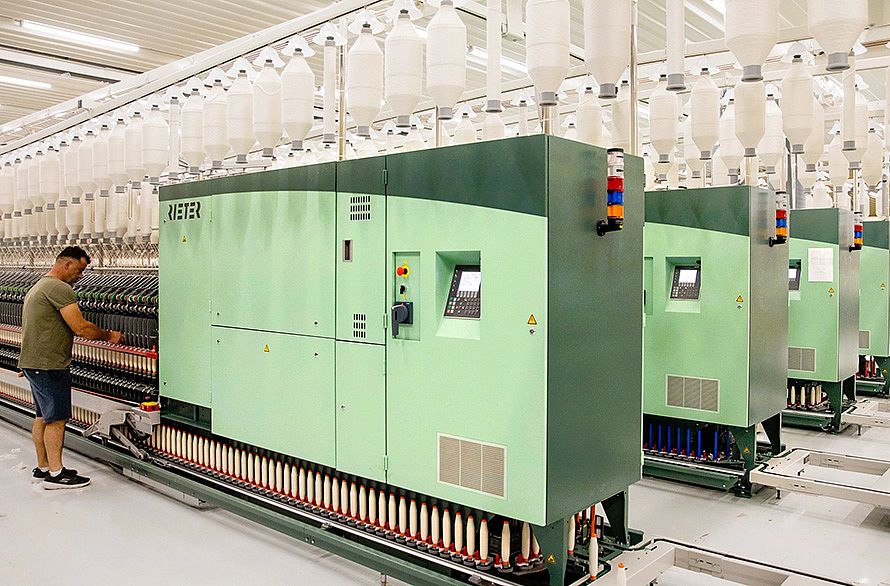

Nafpaktos Textile Industry S.A., based in the same-named city of Nafpaktos in Greece, is a respected player in the global textile market. They produce high-quality yarns in their state-of-the-art production facilities, which include the entire range of processes from cotton ginning to spinning. The company operates a vertically integrated production system that focuses on traceability and transparency from farm to yarn. Nafpaktos is a leading example when it comes to innovative production processes and the use of ESSENTIALmonitor, module of Rieter's all-in-one mill management system, plays an important role for the company.

The Challenge

High breakage rates and inefficient ring spinning machine performance, negatively affect the yarn quality and thus the quality of the end product. To maximize the efficiency and profitability of the ring spinning process, the end break rate must be reduced to a minimum. End breakage is a critical spinning parameter that not only affects the maximum spindle speed, but can also provide indications of yarn quality, mechanical condition of the machinery and the quality of the raw material. This makes it a decisive factor for the success of a spinning mill, and this also applies to the Nafpaktos facilities.

The Solution

In order to address end breakage, effective control is key. Often, high end breakage rates are caused by repeated events occurring in just a few spindles. The individual spindle monitoring ISM premium on their ring spinning machines G 38 enables permanent real-time monitoring of every spindle. Based on this data, ESSENTIALmonitor, module of the Rieter Digital Spinning Suite, monitors the end breaks and analyzes the cops on the G 38. The real-time monitoring system provides accurate data and insights to identify and address spindles giving repeated end breaks and detect defective spindles.

The Customer’s Benefits

Thanks to ESSENTIALmonitor, Nafpaktos was able to significantly reduce its end breakage rates, resulting in higher yarn quality and improved efficiency. By analyzing the cops built up during the spinning process, they were also able to optimize the speed curve in ring spinning to further reduce end breakage rates.

Anastasios Polychronos, Mill Manager of Nafpaktos, was thrilled with the success of the system and praised its ease of use and accurate data analysis.

He could observe following benefits using ESSENTIALmonitor:

- Transparency on quality, production, and energy data

- Enhanced machine productivity, output quality and consistency

- Improvement suggestions to close the gaps based on data

- Planned maintenance to keep the machine uptime

In addition, Nafpaktos' spinning mill benefits from individual spindle monitoring system ISM premium on their ring spinning machines G 38. ISM enables permanent real-time monitoring of every spindle, which allows to detect and correct issues as they occur. The technology is reliable and uses an optical sensor system to detect natural ends down, start-up ends down, slipping spindles, and yarn breaks on the machine end, section, and spindle. ISM can also allocate up to 50% more spindles and provide valuable production data for analysis and process improvement.

We are thrilled with the success of ESSENTIALmonitor and greatly appreciate its ease of use. The system delivers transparency on quality, production, and energy data and thus helps us to improve our processes in the spinning mill overall.Anastasios Polychronos, Mill Manager of Nafpaktos Textile Industry S.A.