J 70: Efficient Air-Jet Spinning of Carded Cotton

The air-jet spinning machine J 70 achieves what was long considered impossible: economic air-jet spinning of carded cotton. This is made possible by a newly developed twist element that improves production speed, yarn strength, and fiber utilization.

Expanding Air-Jet Applications

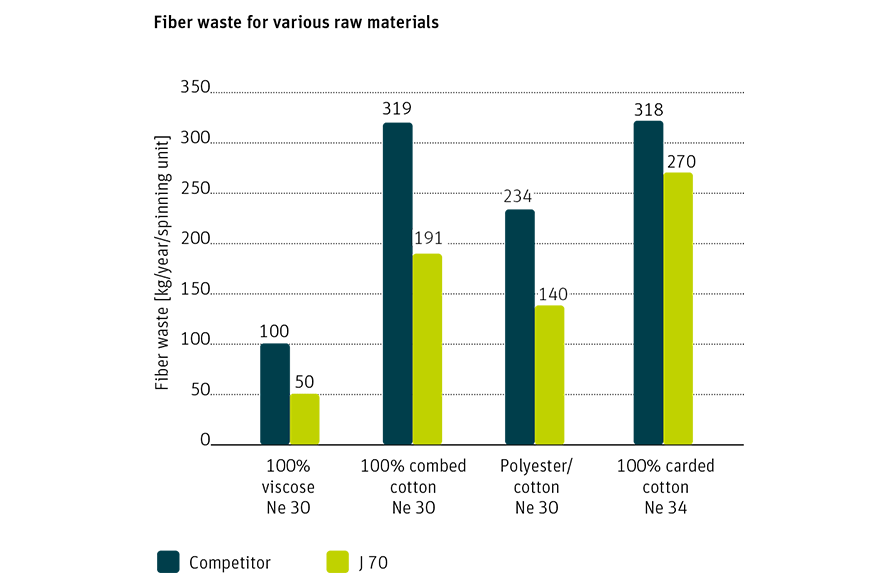

Air-jet spinning machines have traditionally been used mainly for viscose, where the process excels with high speed, low energy consumption, and a distinctive yarn structure. However, spinning cotton and cotton blends has been limited by high fiber loss, making economic production difficult.

Innovative Twist Element

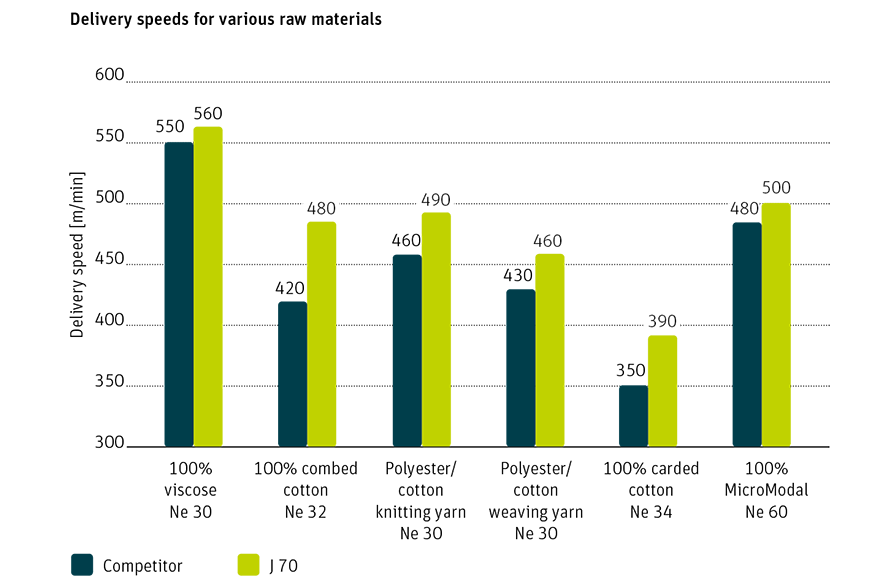

Rieter engineers completely redesigned the key component of the J 70: the twist element. Although only about two centimeters long, it binds fibers more efficiently into the yarn, increasing yarn strength and production speed by around 10%. Combined with the machine’s autonomous spinning positions, the J 70 achieves record speeds.

Higher Efficiency, New Possibilities

The new twist element not only enables higher production speeds, it also reduces fiber loss to a new level. The improved fiber utilization lowers fiber loss in carded cotton for a yarn fineness of Ne 34 to 8–9% at a high delivery speed of 390 m/min. This makes the economical air-jet spinning of carded cotton possible for the first time.

The Perfect Balance of Yarn Quality and Fabric Feel

Field trials have shown that the higher production speed not only maintains but even improves the quality of carded yarn – proven over a production period of six months. In addition, J 70 air-spun yarn impressed with excellent running performance in downstream processing.