Introducing J 70

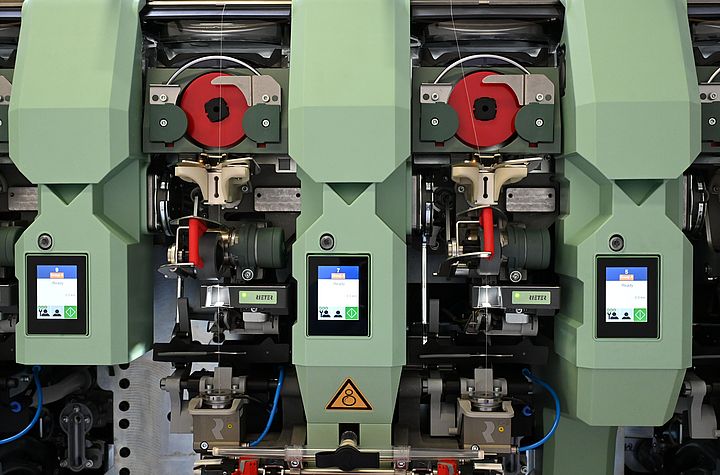

The revolutionary double-sided air-jet spinning machine J 70 with up to 200 autonomous spinning units and four robots allows production speeds at unmatched 600 m/min. Newly developed technology components provide increased delivery speeds in all applications.

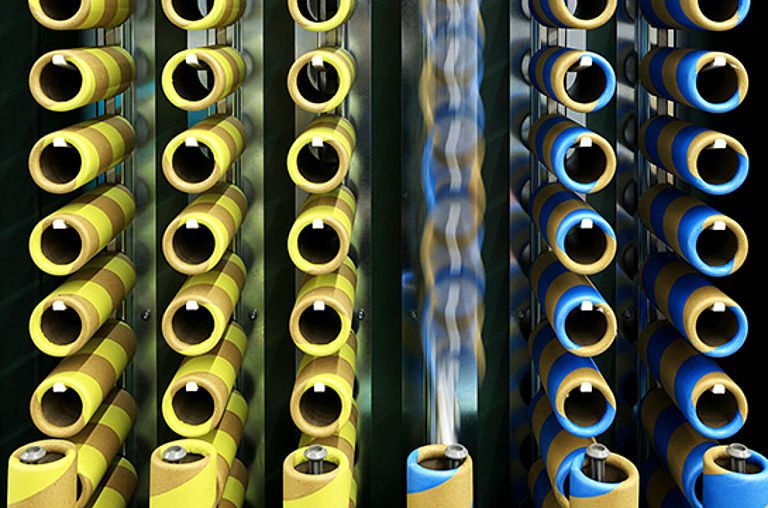

The VARIOlot option offers maximum flexibility to simultaneously spin four lots with independent settings at a time on one machine (two per machine side).

Further reduced energy consumption, highest fiber yield and a low space requirement significantly reduce the overall yarn manufacturing costs.