Pee Vee Textiles Achieves Outstanding Fiber Savings with HYPERTOP C-60

Pee Vee Textiles Limited (PVTL) in Maharashtra, India, enhanced the performance of Rieter card C 70 in cooperation with Graf's application experts. Introducing the HYPERTOP flexible flat into its carding process has brought up to 0.5% good fiber savings with remained consistently high yarn quality. In addition, lower waste levels fully reflect PVTL proactive approach to sustainable production.

Enhancing Fiber Yield Within Existing Systems

Pee Vee Textiles Limited (PVTL) was established by the Mohota family with the vision of building a fully modernized spinning and weaving facility in central India. Over the past three decades, PVTL has grown into one of the country’s leading producers of cotton yarns and synthetic as well as grey fabrics, operating with more than 96 000 spindles, 1 944 rotors, 1 888 Vortex position, 360 position of Rieter air-jet Spinning machines and 616 airjet looms. With a wide global customer base and multiple awards for export excellence, the company is committed to combining volume production with consistent quality and sustainability.

In line with this ambition, PVTL continuously invests in modernization and performance improvement. One of the company’s key objectives was to enhance fiber yield across its spinning operations. The goal: reduce fiber loss, improve cost and carding efficiency, and further stabilize yarn quality, especially in export-critical segments. At the same time, any solution needed to work with existing carding machines and production systems without requiring major investment in new equipment or disruptive changes to processes.

Seamless Integration of HYPERTOP C-60

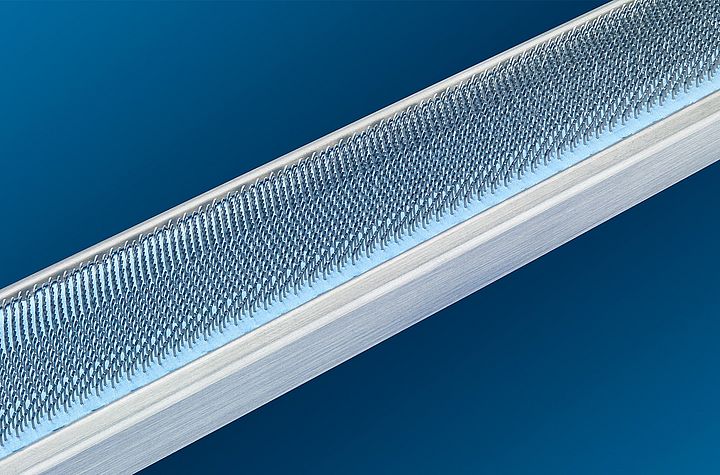

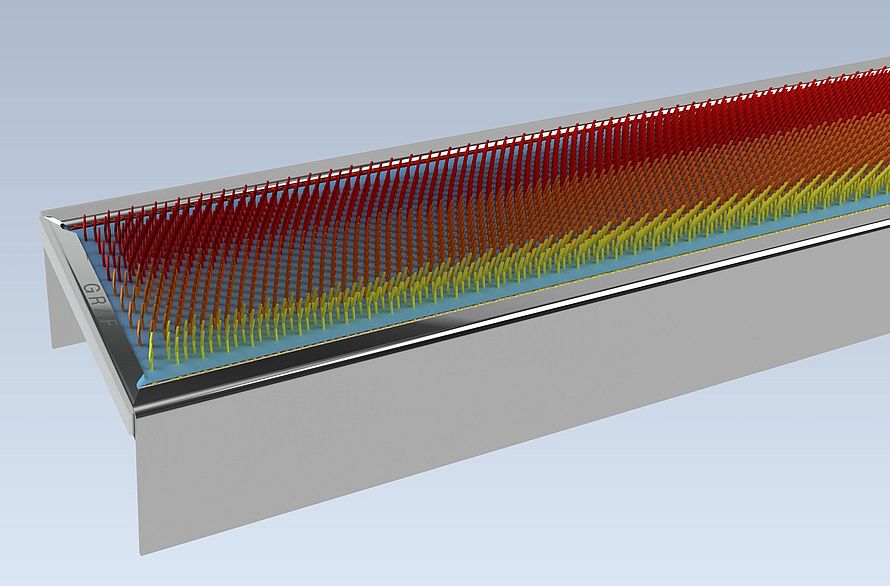

In cooperation with Graf’s application experts, PVTL introduced the HYPERTOP C-60 flexible flat into its carding process. This Swiss Engineered flexible flat features a multizone setting pattern that provides more refined fiber control and precise fiber alignment during the carding operation. HYPERTOP enables better retention of usable fibers, reduces waste, and stabilises output quality – supporting PVTL’s focus on consistent, high-grade yarns.

The implementation was carried out with minimal disruption to ongoing production. Graf’s support team worked closely with PVTL’s engineers to ensure that the integration was smooth and that the new flexible flats were fine-tuned to the mill’s specific operating conditions. From day one, the system delivered measurable improvements.

Five Key Benefits with HYPERTOP and Rieter Carding Technology

- Increased fiber yield

By switching to HYPERTOP C-60, PVTL was able to achieve up to +0.5% good fiber savings. This gain results in higher usable output per kilogram of raw material – a direct benefit for both profitability and resource efficiency. - Consistent yarn quality

Despite the increase in fiber retention, the yarn quality remained at consistently high levels. PVTL continues to meet the demanding standards of its global customers, with stable yarn IPI values across a range of yarn counts. - Sustainability gains

Lower waste levels and more efficient use of fibers directly support PVTL’s environmental goals. The company’s decision to implement HYPERTOP reflects its proactive approach to sustainable production and responsible use of natural and synthetic resources. - Fast payback and long-term return

The benefits of improved fiber yield and reduced waste are evident from the start. PVTL is already seeing a return on investment, with ongoing cost savings expected to increase over the full lifetime of the HYPERTOP system. - Full machine compatibility

HYPERTOP is compatible with all major carding systems, allowing PVTL to optimise performance across its entire range of equipment – regardless of machine type or generation. This flexibility is especially valuable in large-scale operations with diverse production lines. At PVTL, HYPERTOP C-60 was successfully tested and implemented on a Rieter card C 70, where it delivered convincing results right from the start.

The implementation of HYPERTOP has delivered a meaningful optimisation in our production. Fiber yield has significantly improved, and yarn quality remains consistently high. This solution aligns perfectly with our goals for efficiency, quality, and sustainability. Graf’s support throughout the integration process has been excellent.Ashok Akade, Vice President (Technical) of Pee Vee Textiles, Pankaj Mahajan, General Manager Maintenance of Pee Vee Textiles

Download

About Pee Vee Textiles Limited

Pee Vee Textiles Limited, founded in 1990 in Maharashtra, India, is a vertically integrated textile manufacturer with a strong focus on high-performance yarns and grey fabrics. Recognised as a Government of India Star Export House, the company exports over 40% of its production and is known for its reliability, flexibility, and capacity to deliver high volumes at short notice.

Pee Vee Textiles Limited

Samudrapur Jam

442305 Wardha Dist

India