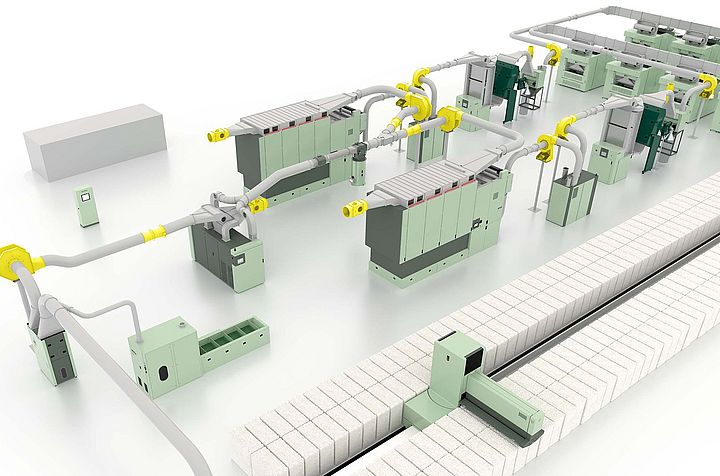

Introducing SERVObale

The semi-automated bale transport system SERVObale is a flexible solution for the efficient placement of bales at the bale opener according to the customer's specified laydown. The use of automated guided vehicles (AGV) instead of forklifts significantly reduces labor workload and minimizes machine downtimes. The AGVs follow predefined paths and instructions precisely. This eliminates human errors such as delivering materials to the wrong location.