Product details

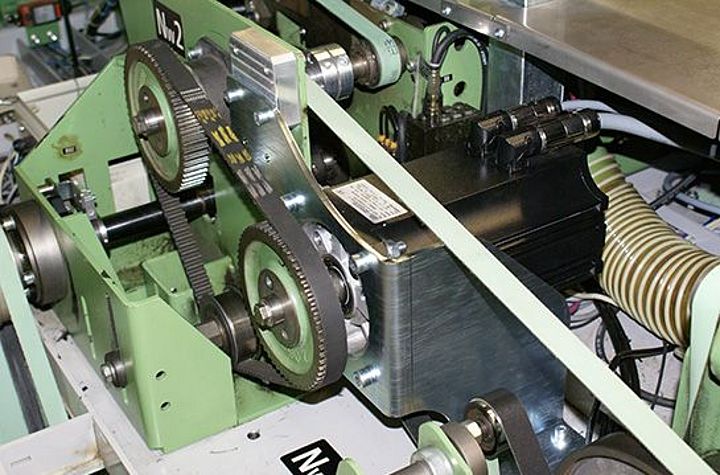

The RSB-D 27 features two machine sides and two autolevelers which work completely independent from each other. This ensures highest production efficiency.

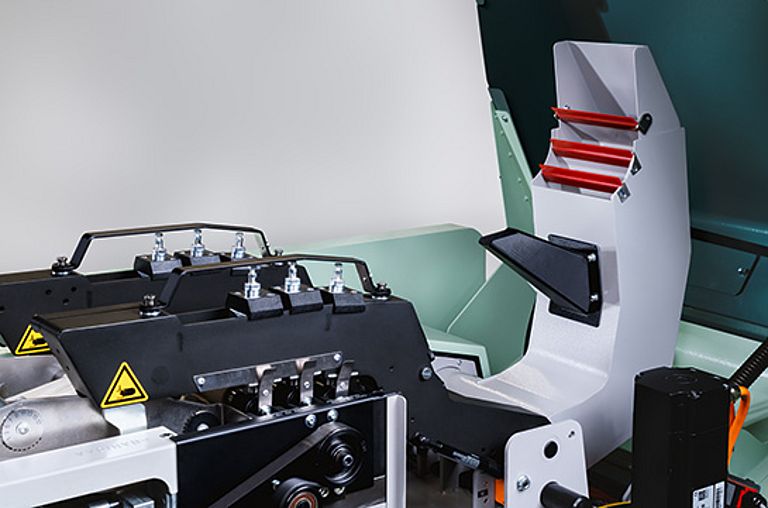

The expert system SLIVERprofessional - integrated in the large 10-inch touchscreen – enhances the processing of recycled fibers with suggestions and further important setting parameters.

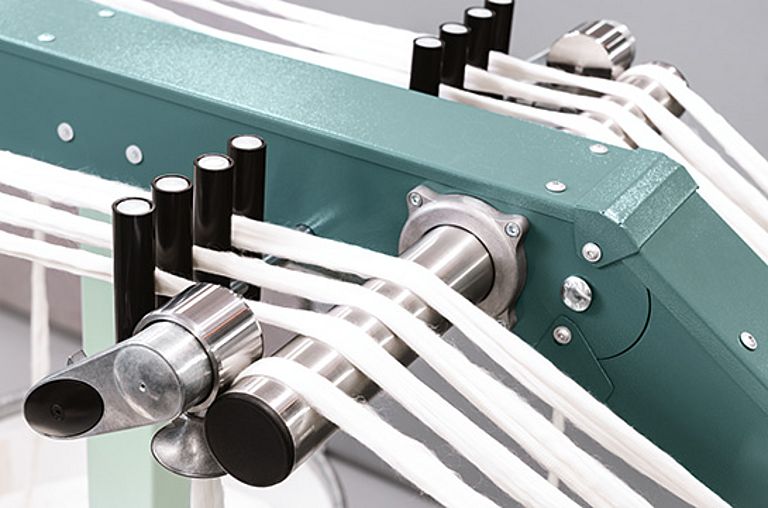

The sliver jam straigthener avoids possible sliver jams in the coiler keeping down stream efficiency high. Its new level of robustness reduces operating costs, while its compact dimensions make it the perfect choice for space-saving applications.