Product details

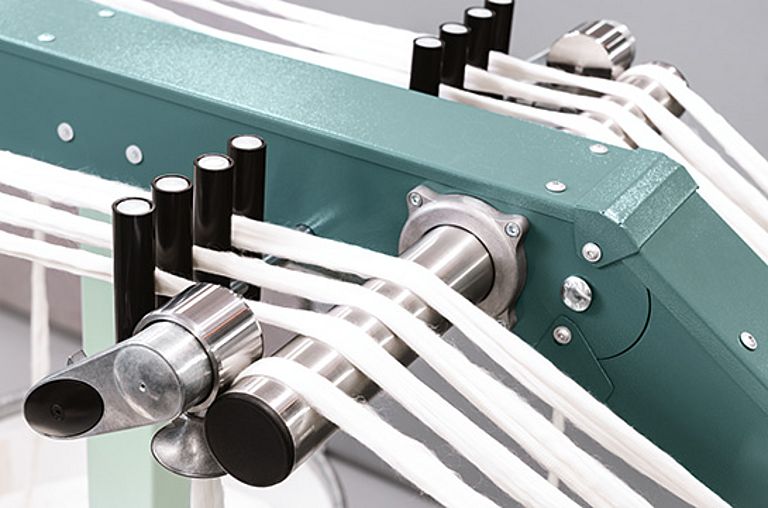

The SB-D 27 is designed for highest productivity of up to 1 200 m/min delivery speed. An active sliver feeding system at machine entry guarantees fast and reliable sliver transport. The rotational can changer for cans up to 1 200 mm diameter ensures highest machine efficiency.

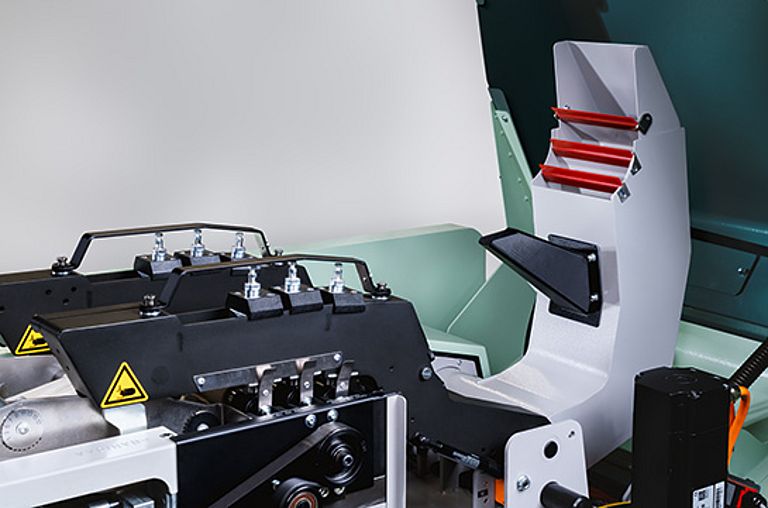

The enhanced expert system SLIVERprofessional can be operated on the large 10 inch touchscreen to quickly change assortments.

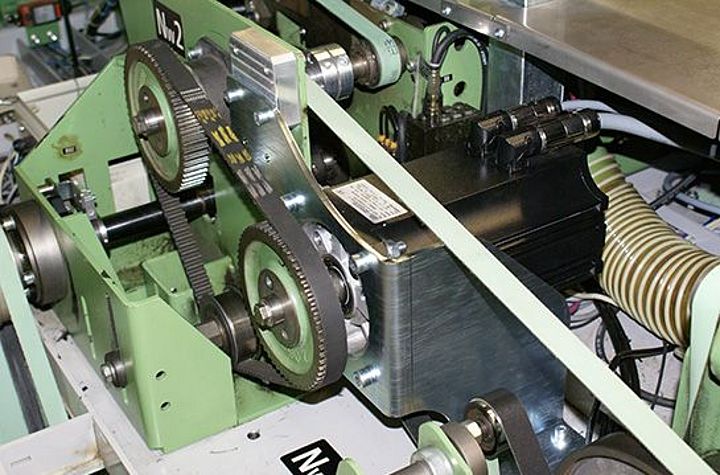

Energy costs are kept to a minimum through the use of the ECOrized drive concept and the compact dimensions make it the perfect choice for space-saving applications.