ROBOdoff: Rotor Yarn Production with Unprecedented Efficiency

Rieter semi-automated rotor spinning machine R 37 with ROBOdoff in the Shunyuan Textile mill

Shunyuan Textile’s extensive experience and deep understanding of processing cotton waste has led to strategic investments in high-quality machinery from Rieter such as the rotor spinning machines R 36 and R 37 as well as autoleveler draw frames RSB-D 26 to replace old local machines. By integrating the device for automated package change ROBOdoff on their rotor spinning machines R 36 and R 37, Shunyuan Textile was able to reduce the operator load to a minimum while keeping their productivity high and even enhance their quality. Shunyuan Textile’s yarn enjoys tremendous market demand – a proof to its quality and value.

The Challenge

Each semi-automated rotor spinning machine in Shunyuan Textile’s mill produces five to six tons of yarn daily. However, the high production output increases the labor required for doffing and packaging, which are the most labor-intensive aspects of rotor yarn production. Finding reliable operators for this in the long term is a challenge for Shunyuan Textile.

Meanwhile, weaving mills face their own unique challenges. Yarn breaks during the warping process significantly increase workloads and impair warping efficiency. The weaving process requires yarn of superior evenness and high strength, which places increased quality demands on the yarn production at Shunyuan textile.

The Solution

To tackle labor-related challenges and reduce the workload, two fundamental strategies emerge: Firstly, enhancing machine efficiency and secondly, elevating the automation level.

The Rieter semi-automated rotor spinning machines R 36 and R 37 feature an optimized spinning box that dynamically adapts to changing customer demands and a wider range of raw materials. The excellent spinning stability ensures highvolume production at a high production speed, ultimately improving yarn quality. This is essential for downstream processes and enhances the competitiveness of Rieter’s customers.

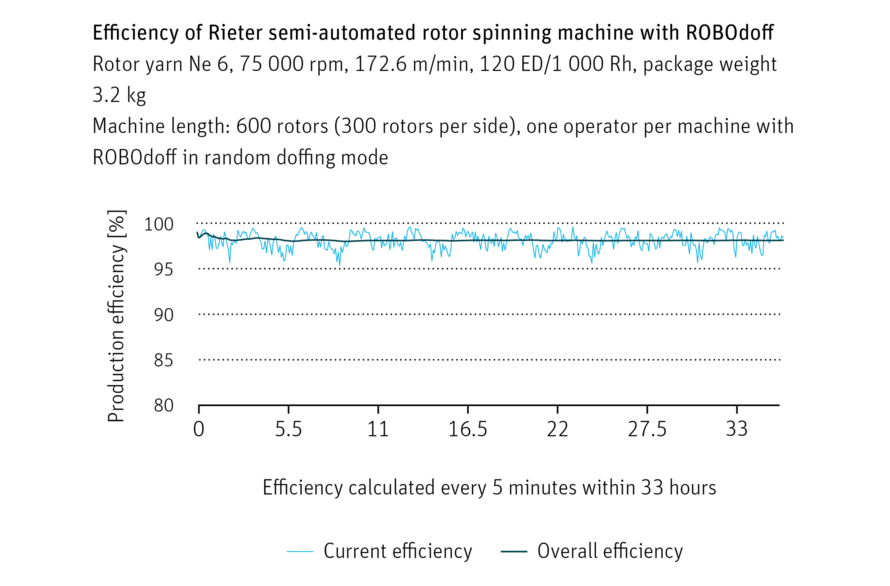

To address the labor-intensive doffing process in rotor spinning, Rieter has introduced ROBOdoff. This innovative solution not only automates doffing, allowing operators to concentrate on piecing, but also boasts an exceptional success rate and precise yarn reserve formation. The result is a significant improvement of efficiency for both spinning mills and downstream processes.

The Customer’s Benefits

Shunyuan Textile integrated Rieter’s rotor spinning machines R 36 and R 37 to produce yarn that features exceptional evenness, reduced hairiness, and impressive strength. This resulted in significant advantages for the following warping processes with fewer breakages and heightened efficiency. The high evenness and reduced imperfections in the yarn result in a woven fabric with a clear, appealing appearance that is enthusiastically received by Shunyuan Textile’s downstream customers.

Thanks to ROBOdoff, Shunyuan’s end-spinning operator team now works with only five employees per shift. Package change takes place without stop of spinning and the most exhausting work is supported or replaced. The overall production has increased because operators focus on managing ends down instead of manual doffing.

Rieter’s semi-automated rotor spinning machine R 37 is known for its exceptional quality, solid stability, and remarkable durability. With its high trash extraction capabilities, the machine consistently delivers toptier, stable yarn that is highly appreciated by our downstream customers. Thanks to the remarkable efficiency of ROBOdoff, we could not only minimize labor intensity, but also reduced our overall yarn production costs.Wang Jiaxiu, Owner of Shunyuan Textile

Download

About Shunyuan Textile

Guangrao Shunyuan Textile Co. Ltd., situated in Guangrao County, Shandong Province, has been a major player in the production of rotor yarn since its establishment in 2002. With over two decades of experience, the company has identified its niche: producing high-quality cotton rotor yarn with a focus on coarser yarn counts to supply the weaving denim industry.

Guangrao Shunyuan Textile Co. Ltd.

Damatou Town, Guangrao County

257337 Dongying City