COMPACTeasy: Boosting Productivity by 10% at Grupo Scala Textil

Jordi Ayguasenosa, Manufacturing Director at Aztlán Textil and Azul Textil, appreciates the improvements achieved with COMPACTeasy.

Grupo Scala Textil, a leading textile manufacturer in Mexico, upgraded 28 ring spinning machines with Rieter’s mechanical compacting system COMPACTeasy at two of its spinning facilities. The upgrade delivered up to 10% higher productivity and significant improvements in yarn quality, strengthening the company’s competitiveness in the Mexican market.

Grupo Scala Textil operates three spinning facilities: Aztlán Textil, Azul Textil, and Scala Textil. Facing rising competition from imported low-cost yarns, the company set out to cut conversion costs by boosting productivity while maintaining its high yarn quality standards.

To achieve this, customers were looking for a compacting device that could be retrofitted quickly, with minimal modifications and without additional energy consumption. For this, Grupo Scala Textil approached Rieter for a suitable compacting system to implement at Aztlán Textil and Azul Textil facilities.

COMPACTeasy is the ideal solution for producing compact yarn, as we upgraded our existing ring spinning machines without costly or complex modifications. This led to increased productivity, improved yarn quality, and greater flexibility in producing various yarn counts. As a zero-energy compacting device, it has helped reduce our overall conversion costs.Jordi Ayguasenosa, Manufacturing Director, Aztlán Textil and Azul Textil

Mechanical compacting without extra energy costs

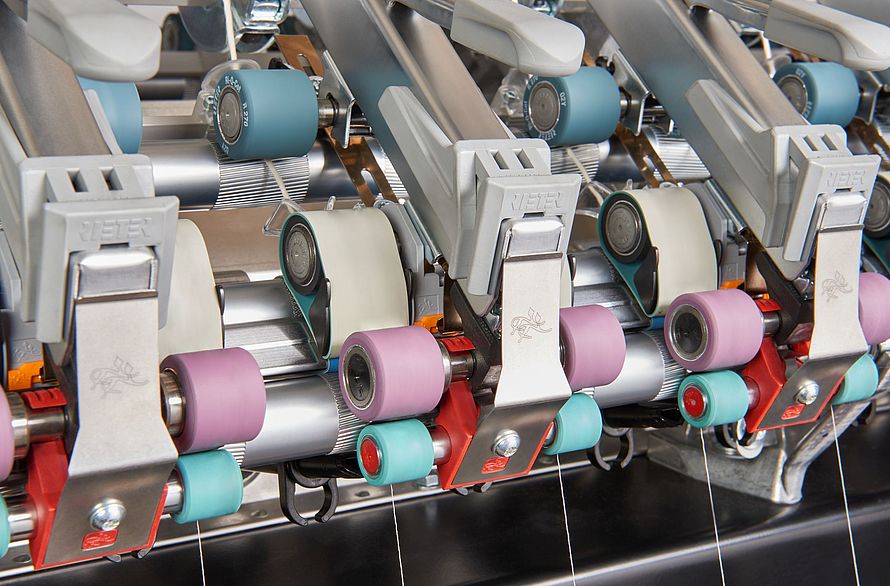

Rieter’s after-sales team proposed COMPACTeasy, a zero-energy mechanical compacting system for higher productivity and cost optimization. The solution was implemented on 17 ring spinning machines G 32 with 1 104 spindles each at Aztlán Textil, and on 11 ring spinning machines G 37 with 1 248 spindles each at Azul Textil.

The machines produce compact yarns from 100% cotton with yarn count Ne 40 and Ne 50. Compacting is performed mechanically in the y-channel, leading to excellent yarn characteristics.

COMPACTeasy also allows for reduced twist per inch (TPI), thereby increasing productivity. Additionally, the mechanical compacting system enables a 6 mm traverse motion – an important advantage that significantly extends cot lifetime and ensures consistently high yarn quality over time.

Rieter’s compact spinning system drives long-term success

With COMPACTeasy, Grupo Scala Textil achieved significant improvements in both productivity and yarn quality. Productivity increased by 10% thanks to reduced twist per inch and higher spindle speeds. The hairiness index decreased by 23%, from 5.6 to 4.3. Single yarn strength (RKM) improved by 3%, while yarn imperfections (IPI) were reduced by 8%.

All of this was accomplished without any rise in power consumption, since the compacting device requires no additional suction motor. Grupo Scala Textil is highly satisfied with the Rieter solution, which helps the company maintain a strong competitive edge in the Mexican yarn market.

ABOUT GRUPO SCALA TEXTIL, MEXICO

Founded in 1965 and headquartered in Puebla, Grupo Scala Textil is one of Mexico’s leading textile groups. The company operates three spinning mills and produces high-quality yarns from 100% cotton, polyester, and polyester-cotton blends. With a production capacity of up to 1 500 tons of yarn per month, Grupo Scala Textil uses both ring and rotor spinning technologies to serve markets in Mexico, Central America and beyond. Its success is built on continuous modernization and a strong commitment to quality.