Doubling Recycled Cotton in Yarn Through Cellulose Fibers

Replacing virgin cotton with Birla’s Excel cellulose fibers makes it possible to spin yarns with 40% recycled cotton instead of the usual 20%. The resulting blends show superior evenness, fabric appearance, and pilling behavior, while remaining fully recyclable. These findings are confirmed by Rieter's latest technology report.

What happens if recycled cotton fibers are blended with cellulose fibers instead of the usual virgin cotton fibers? The proportion of recycled cotton in the yarn can be significantly increased. One reason for this is the fact that cellulose fibers have a constant fiber length.

A comprehensive trial was conducted in collaboration with Indian fiber manufacturer Birla Cellulose and Recover, the Spanish manufacturer of recycled cotton fibers. The aim was to produce sustainable, recyclable yarn with a high proportion of recycled cotton fibers. To reach this, the recycled cotton fibers were not blended with virgin cotton fibers, as usual. Instead, the sustainable cellulose fiber produced by Birla called Excel was added to the recycled fibers.

Cellulose fibers and recycled cotton – a blend with many advantages

One major advantage of synthetic cellulose fibers is that they have a consistent fiber length. When blended with recycled cotton, this increases the average fiber length while reducing the proportion of short fibers, which improves spinnability on the ring spinning machine. Another advantage is that the yarns are composed of 100 percent cellulose fibers, which preserves the typical cotton character and enables further recycling.

Twice the recycled content, even better quality

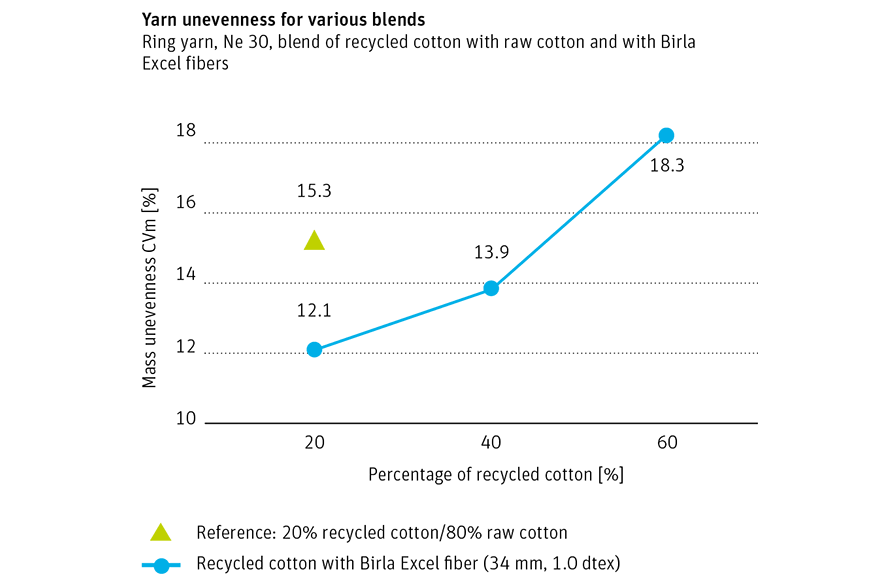

The yarn commonly used in practice, consisting of 20% recycled cotton and 80% virgin cotton, served as a reference. In all other test trials, the raw cotton was replaced by various Birla Excel fibers and mixed with varying proportions of recycled cotton, spun, and processed into the final product. The yarn with twice the recycled content was particularly impressive: 40% recycled cotton and 60% Birla Excel fibers (fiber length 34 mm, fiber fineness 1.0 dtex). The blend achieved superior results:

- significantly better yarn evenness,

- much more even fabric appearance,

- better hairiness, and

- better pilling behavior.

A sustainable option to produce high quality recycled yarn

Replacing raw cotton with sustainably produced cellulose fibers significantly improves yarn quality, spinning performance, downstream processing, and the end product. It is a way to create more sustainable products with new fibers.