From Upgrade to Breakthrough: COMPACTapron Powers Rajaguru’s Growth

Balamukunthan Sivakumar, Joint Managing Director, Rajaguru Spinning Mills Pvt. Ltd., South India’s viscose pioneer, counts on Rieter’s COMPACTapron.

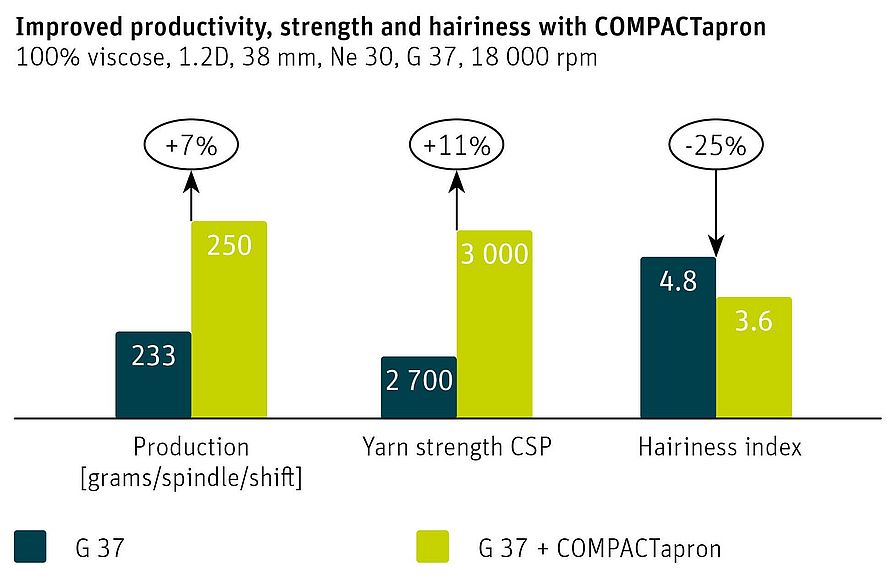

Rajaguru Spinning Mills Pvt. Ltd., India, produces 100% viscose compact yarn using Rieter’s compacting device COMPACTapron. The integration of COMPACTapron across 21 ring spinning machines G 37 resulted in a 7% increase in productivity, an 11% improvement in yarn strength and a 25% reduction in yarn hairiness.

In today‘s highly competitive textile industry, spinning mills must balance two critical yet often conflicting objectives: delivering superior yarn quality and achieving maximum output. Rajaguru Spinning Mills Pvt. Ltd. has shown that it’s possible to achieve both, thanks to the capabilities of Rieter technology. Since its founding in 1993, Rajaguru Spinning Mills Pvt. Ltd. has made a name for itself as one of the largest viscose yarn manufacturers in South India, operating 160 000 spindles with a production capacity of 110 tons per day.

A pioneer in producing 100% viscose yarn and blends, the mill caters to customers who demand high yarn strength and consistency to ensure excellent downstream performance, particularly for air-jet weaving applications. To meet evolving market requirements, Rajaguru turned to Rieter for a proven compacting solution to further enhance yarn quality and increase productivity.

Strategic upgrade: Why Rajaguru chose COMPACTapron

To address the growing demand for higher yarn performance, the Rieter After Sales team recommended the compacting device COMPACTapron as a value‑adding upgrade. Successful trials conducted at this mill using a COMPACTapron trial kit clearly demonstrated performance improvements. Based on these results, the customer decided to upgrade 21 ring spinning machines G 37, each equipped with 1 344 spindles, for spinning viscose yarns in the count range Ne 10 to Ne 60.

Higher yarn strength with 3D compacting technology

Thanks to its unique 3D compacting technology, COMPACTapron transports fibers through the condensing zone over the suction slot in a distinctive distance to the mesh apron. This ensures all fibers are entirely compacted. The distance between the nip lines is shorter than the shortest fiber, enabling precise fiber guidance through the compacting zone. This results in better yarn tenacity, which outperforms competitor systems. Additionally, this enhanced compacting of fibers significantly reduces yarn imperfections, improves uniformity and lowers hairiness.

Efficiency and sustainability at its core

Engineered for operational excellence, COMPACTapron features a simplified design with a single large diameter cot, resulting in almost no lapping. COMPACTapron achieves up to 60% lower energy consumption compared to other four roller compacting systems. This is made possible by its optimized suction slot design, which reduces airflow requirements, and by using the existing pneumafil suction system, eliminating the need for an additional fan motor. These advantages make COMPACTapron a smart and sustainable investment for spinning mills.

COMPACTapron is the most suitable solution for us to produce viscose compact yarn. It has helped us achieve better yarn quality, increased productivity and greater flexibility in producing different yarn counts.Balamukunthan Sivakumar, Joint Managing Director, Rajaguru Spinning Mills Pvt. Ltd., India.

A solution that delivers: productivity, strength and hairiness improved

Rieter’s COMPACTapron stands out as a breakthrough in compact-spinning technology, enabling South India’s viscose leader to reconcile two seemingly opposing objectives of speed and quality, delivering tangible advantages to Rajaguru Spinning Mills. The installation of COMPACTapron on the existing ring spinning machines G 37 led to the following benefits while processing yarn count Ne 30 with 100% viscose fiber:

- 7% increase in productivity,

- 11% increase in yarn strength and

- 25% reduction in yarn hairiness.

The plug-and-play design of COMPACTapron is compatible with a wide range of Rieter ring spinning machine models. Its versatility allows spinning mills to optimize raw material usage, adjust twist levels for productivity improvements and respond flexibly to diverse market requirements. By integrating this advanced compacting solution, spinning mills can achieve superior yarn quality, reduce operational costs and enhance overall productivity. This stands as a testament to Rieter's commitment to innovation, quality and sustainability.