R 37: Production of High-Quality Yarn Made from 100% Polyester

Enzhong Lv, Nuogao Fiber General Manager

Nuogao Fiber in China produces high-quality 100% polyester yarns with outstanding consistency and efficiency using the Rieter R 37 rotor spinning system with ROBOdoff. The advanced setup ensures stable, high-speed production, automated doffing, and uniform package quality, delivering superior yarns that enhance downstream fabric performance and strengthen Nuogao’s market competitiveness.

High-Count Polyester Yarn Tests Quality, Efficiency, and Costs

Producing 100% polyester yarn in high counts places extremely high demands on rotor spinning machines.

Conventional rotor spinning machines often face challenges such as high breakage rates, low production efficiency, unstable yarn quality, high yarn faults, and poor fabric surface quality when manufacturing 100% polyester yarn.

Furthermore, downstream weaving and knitting markets demand consistent yarn package length and weight to minimize downstream yarn waste. The consistency of yarn package length directly affects mills’ raw material utilization rate and production costs. How to effectively reduce production costs while improving yarn quality has become a key challenge for Nuogao.

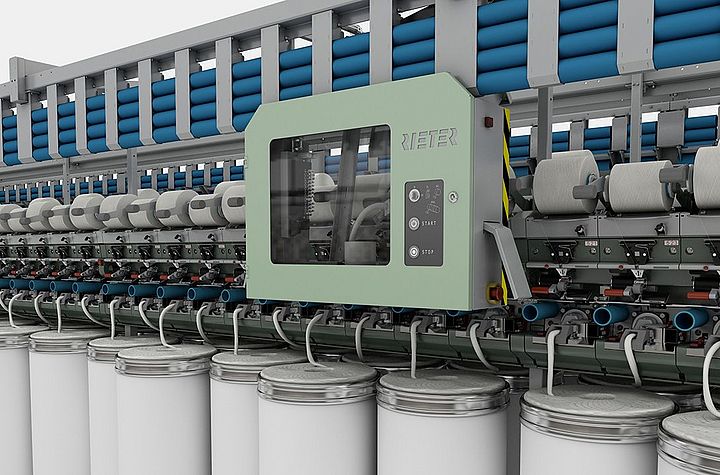

Rieter R 37 with Robodoff Ensures Stable, Fast, and Consistent Yarn

The Rieter rotor spinning machine R 37 delivers excellent spinning stability, ensuring high production at high speed while maintaining low breakage rates. Thanks to its unique redesigned spinning box and optimized spinning components, the R 37 enables efficient fiber opening while protecting fibers from damage when producing high-count 100% polyester yarns. This ensures stable yarn quality and excellent fabric evenness. In the downstream market for 100% polyester rotor yarn in high counts, the yarns produced by the R 37 have become the preferred choice.

The automatic doffing system ROBOdoff does not only automate the unpleasant task of manual doffing, but it also ensures that all doffed packages have the same package length. The automatic doffing system works as a traveling cleaner when doffing is not required. It cleans the rail and the machine’s spinning positions, providing customers with dual flexibility.

98%+ Efficiency, Less Labor, Minimal Waste, and Top-Quality Yarn

After being put into operation, the R 37 has maintained a stable operating efficiency of over 98%. Taking the production of 100% polyester yarn with a count of Ne 16 as an example, the delivery speed can reach 153 m/min, with a stable daily output of approximately 3.7 tons per machine. With only four operators required to monitor all five machines, it significantly reduces both labor demand and workload. The fixed-length doffing feature of ROBOdoff ensures minimal deviation in package weight. During packaging, each bundle can be precisely controlled to consist of eight standard yarn packages, eliminating the need for manual weighing and matching, which remarkably enhances production efficiency. In downstream weaving or knitting processes, yarn waste has been reduced, and efficiency has noticeably improved. Additionally, another advantage of the ROBOdoff is a consistent and proper formation of the transfer tail.

Moreover, the stable production process significantly enhances the consistency of yarn quality, providing downstream customers with a more reliable supply of superior raw materials. This strengthens Nuogao’s competitive edge in the market.

The R 37 operates with outstanding stability, producing yarn of consistent and exceptional quality with superior evenness. Feedback from our downstream customers indicates that fabrics made from R 37 rotor yarn feature a smoother surface, enhanced softness, and a marked improvement in overall quality.Enzhong Lv, General Manager

Download

About Nuogao Fiber

Xuzhou Nuogao Fiber Technology Co., Ltd. is a Chinese textile company specializing in synthetic fiber production and processing. Founded in 2021 in Xuzhou, Jiangsu Province, the company focuses on manufacturing high-quality fibers for fabric production and textile applications. In 2024, it expanded its operations with a new production facility, equipped with advanced fiber spinning and finishing equipment, increasing efficiency and reducing reliance on external suppliers.

Xuzhou Nuogao Fiber Technology Co., Ltd.

Datun Sub-district Office

Peixian County

221600 Xuzhou City

China