Product details

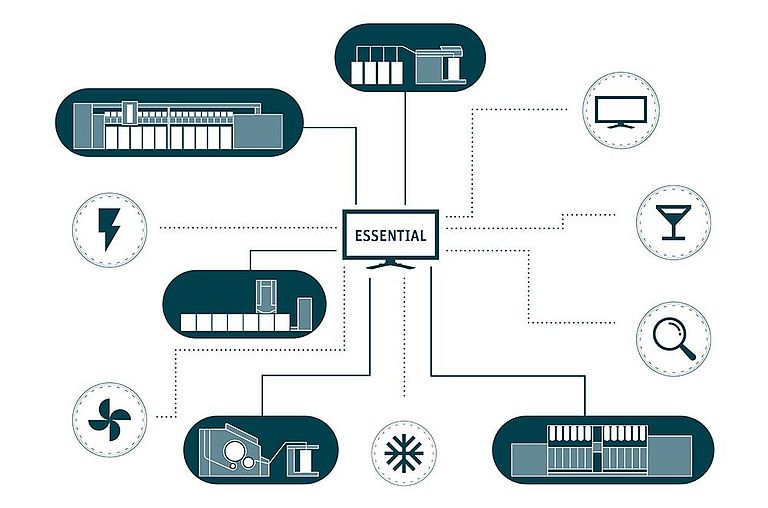

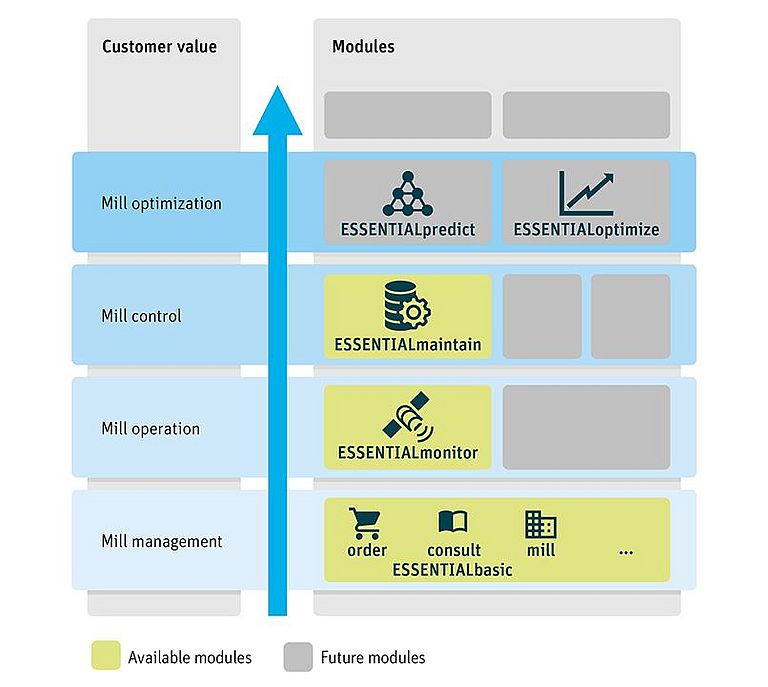

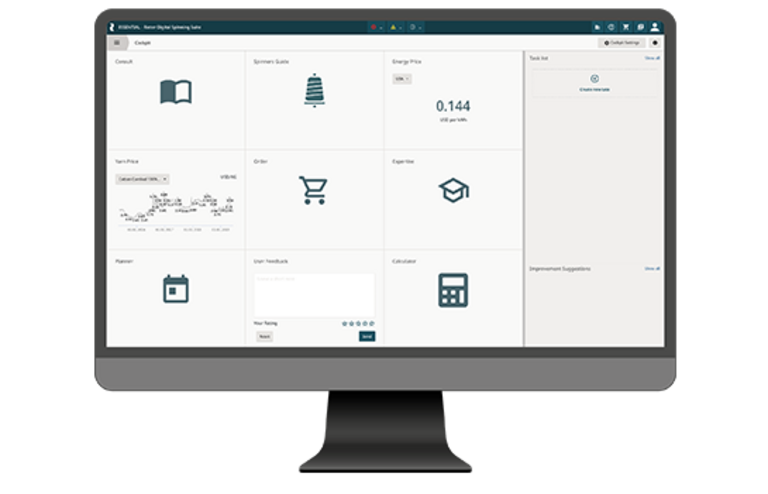

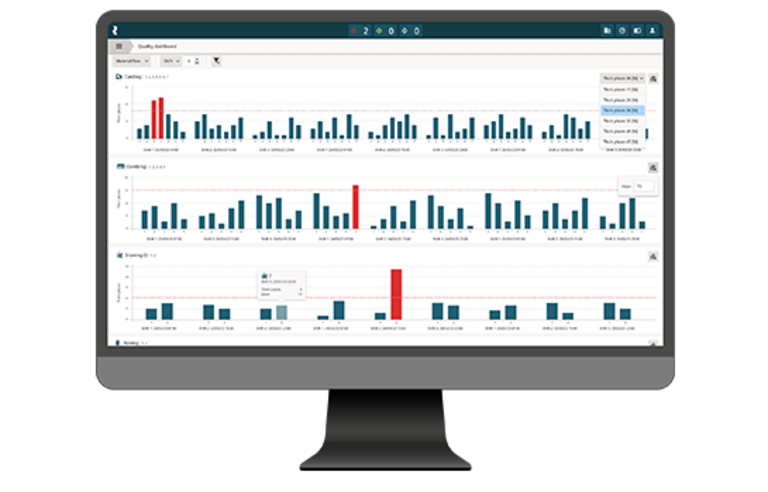

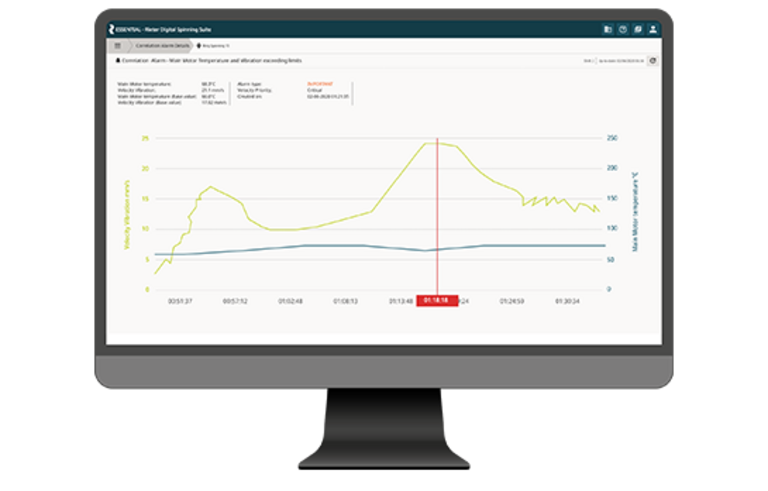

ESSENTIAL leverages digital technology for the textile value creation. The Rieter Digital Spinning Suite analyzes data of the entire spinning mill in real-time and provides meaningful key performance indicators based on this.

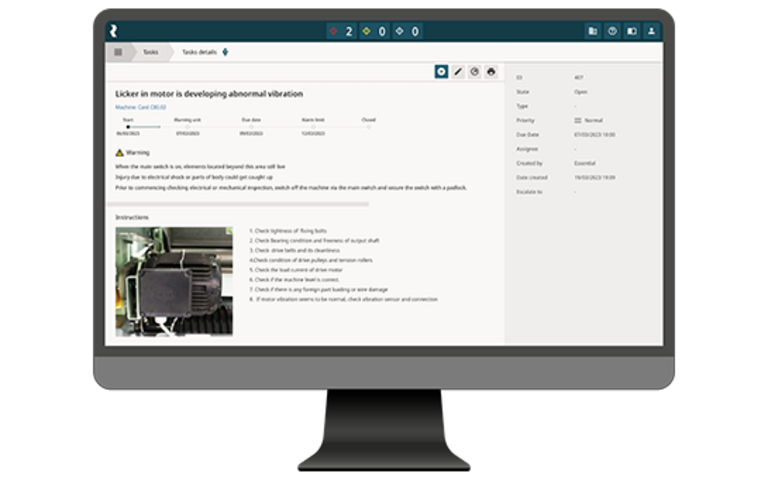

With comprehensive and clearly arranged digital analysis, the system supports management in strengthening the expertise of mill staff, eliminating inefficiencies and optimizing processes across the entire system. Through its holistic approach, ESSENTIAL is connecting the dots in the spinning mill.