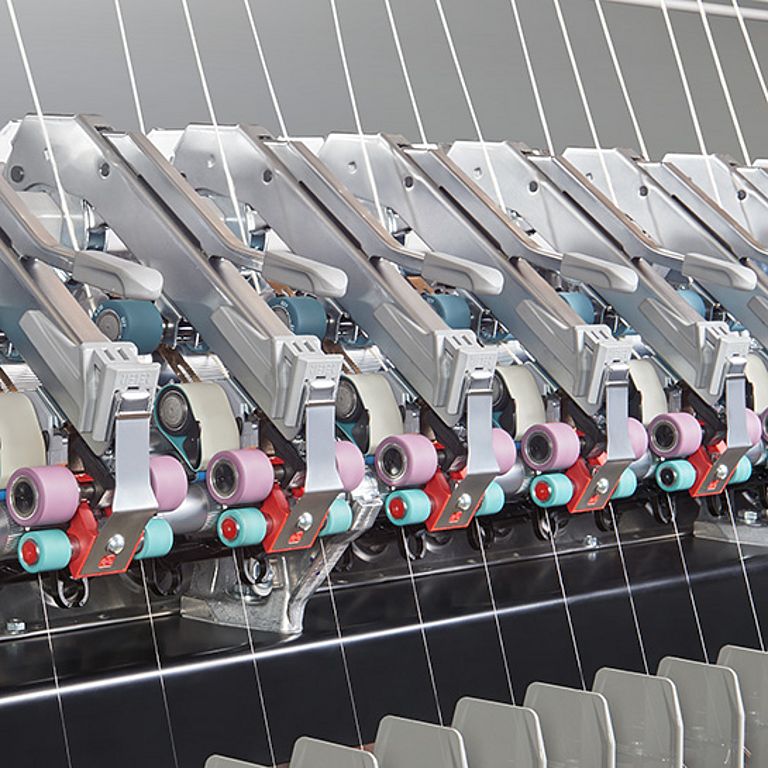

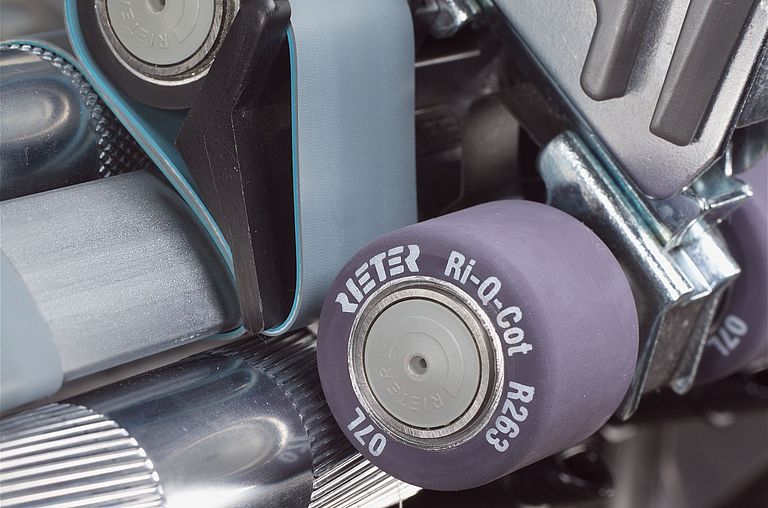

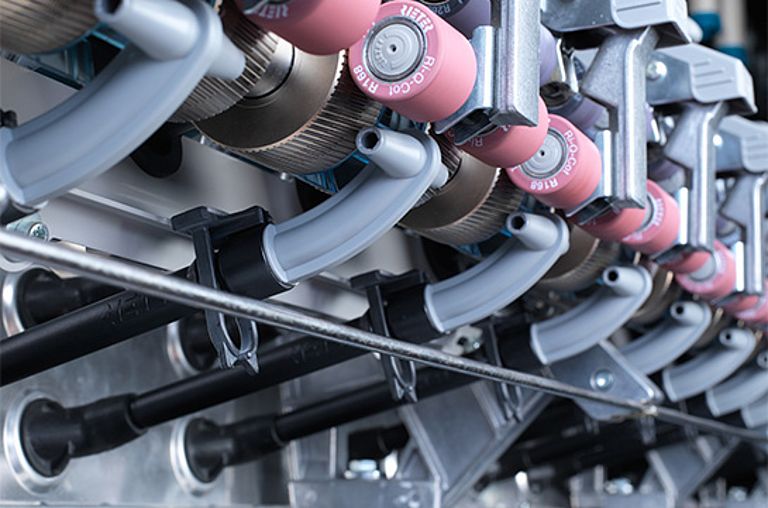

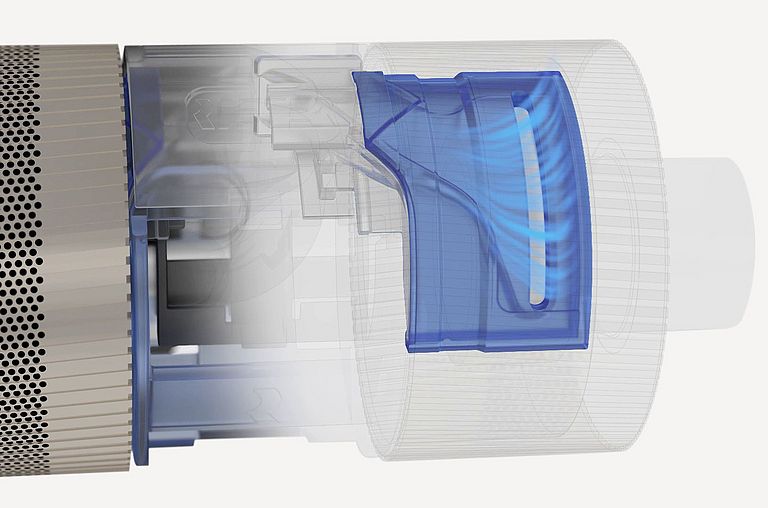

Rieter offers innovative compacting solutions according to customer needs. With an easy installation and removal, Rieter compacting devices allow to switch between ring and compact yarn within seconds, offering the right solution to obtain a perfect integration of the edge fibers into the yarn.

Three different compacting devices:

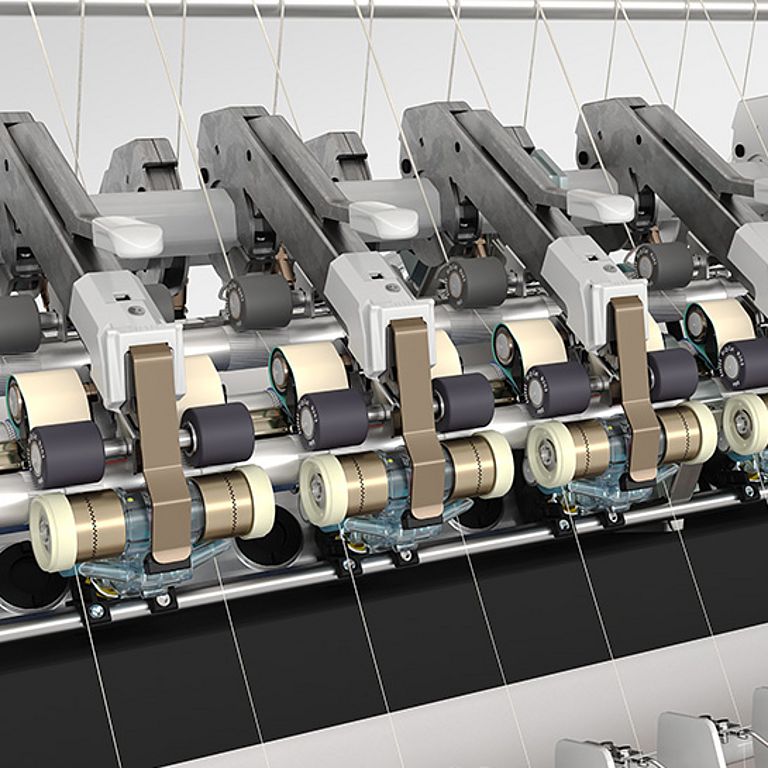

-COMPACTdrum, for Rieter ring spinning machines, adds a new dimension in hairiness reduction from yarn to fabric.

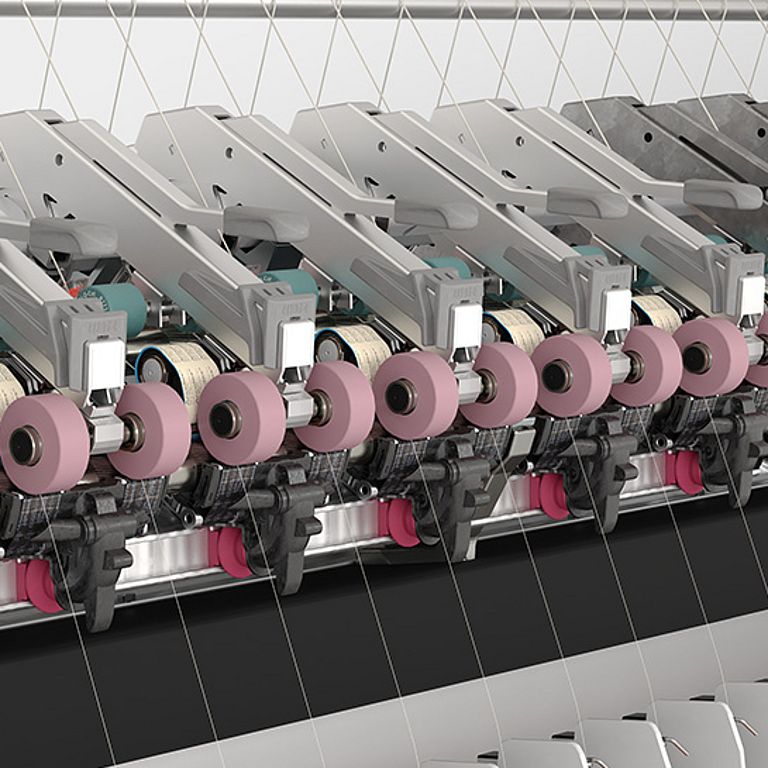

-COMPACTeasy, the mechanical compacting solution, requires low investment and zero energy thanks to its y-channel resulting in an intensive double compacting.

-COMPACTapron, the new generation lattice apron compacting technology, offers the best yarn tenacity values thanks to its 3D technology, ensuring 90 - 100% control of the fibers.