Smart Winding Machine Upgrades for More Sustainable Yarn Production

Atul Kumar Singh, Plant Head at PT Indo-Rama Synthetics Tbk, Indonesia, is happy with the improvement achieved through the winding machine upgrades.

In today’s fast-evolving textile market, staying competitive means continuously improving efficiency, quality and sustainability. In order to sharpen its competitive edge, PT Indo-Rama Synthetics Tbk, a textile leader in Indonesia, partnered with Rieter to enhance winding performance through targeted upgrades such as new suction nozzles, power nozzle Smartjet and OZ2 prisms for splicing. These improvements boosted energy efficiency, machine output and splice quality.

PT Indo-Rama Synthetics Tbk operates the winding machines Autoconer 338, Autoconer X5 and Autoconer 6 to process Ne 20, Ne 30 and Ne 34 counts of 100% cotton compact yarn, 100% polyester yarn and a variety of blended yarns. To reduce conversion costs and maintain competitiveness, the company approached Rieter for a solution to improve energy efficiency, machine performance and splicing quality while also reducing operator workload.

We have seen an appreciable improvement in productivity, quality and energy efficiency following these winding machine upgrades. The enhanced features on our existing machines have helped us reduce conversion costs, making us more competitive.Atul Kumar Singh, Plant Head at PT Indo-Rama Synthetics Tbk, Indonesia.

Tailored yarn winding machine upgrades for measurable impact

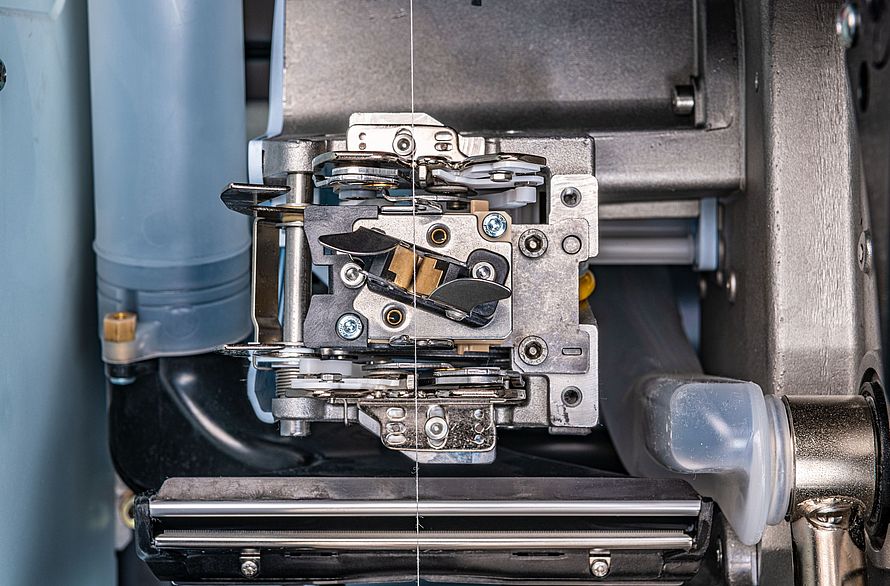

After analyzing the operational requirements, Rieter’s After Sales team proposed a package of targeted upgrades to enhance yarn winding machine performance and efficiency. These included the replacement of the standard suction nozzles with the new flow-optimized suction nozzles, designed with aerodynamically refined inner and outer shapes to ensure more efficient air guidance and lower energy demand.

In addition, the Smartjet power nozzle was recommended for installation on the doffer unit to improve the upper yarn search and increase the success rate of yarn pick-up during the yarn search cycle sequence. The team also suggested the latest open prism splice technology, which offers to improved splicing quality, easier process handling and greater flexibility. It is now also possible to use the recommended open prism OZ2, covering of a wider yarn count range for diverse applications.

Proven upgrades driving efficiency and competitiveness

With these upgrades, PT Indo-Rama Synthetics Tbk realized several advantages in energy savings, higher productivity and improved yarn quality.

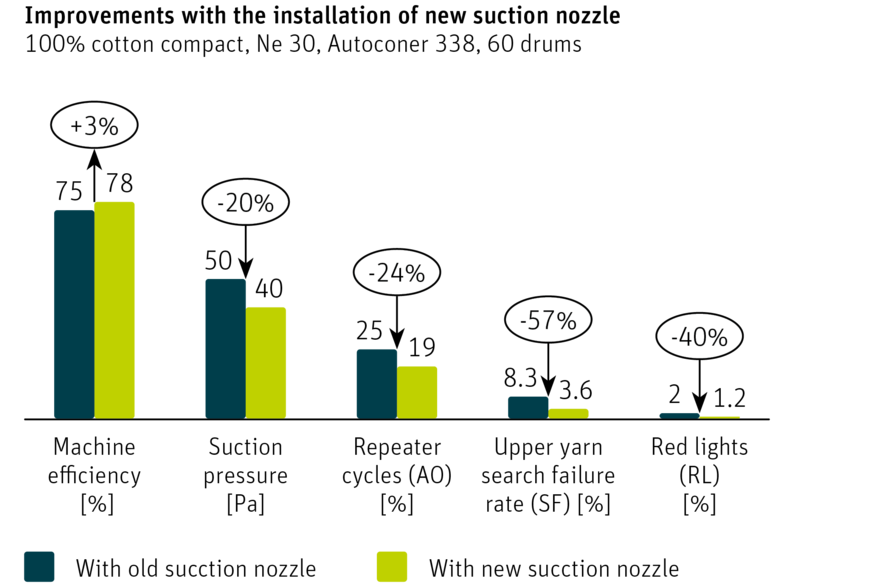

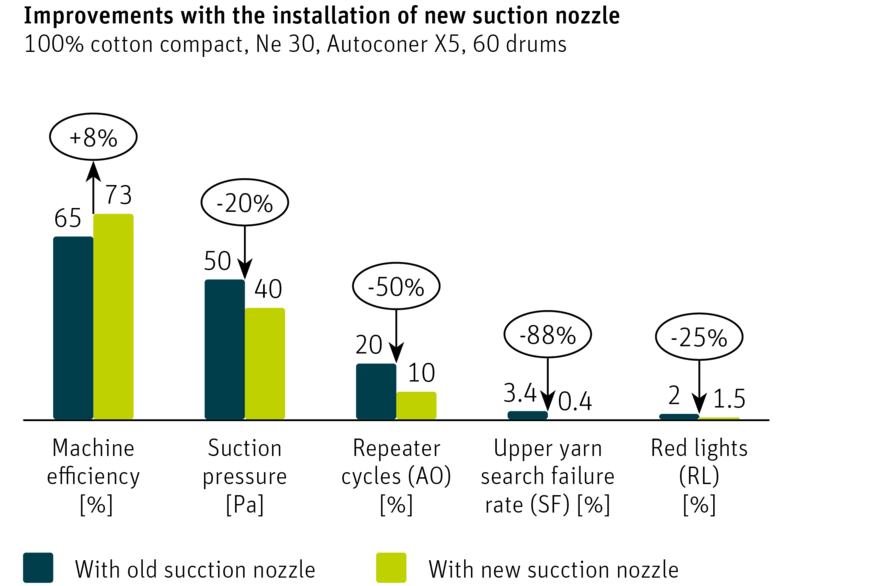

- The optimized suction nozzle lowered suction pressure demand by 20%, leading to significant energy savings.

- The Smartjet power nozzle upgrade significantly reduced the upper yarn search failure rate (SF%), increasing machine efficiency by up to 8%.

- The OZ2 open prism technology improved average splice strength of the yarn by up to 4% and reduced compressed air usage.

Together, these improvements not only enhanced machine performance but also streamlined daily operations for greater efficiency. As a result, the company is well-positioned to meet customer demands with higher yarn quality at lower production costs.

About PT Indo-Rama Synthetics Tbk

Founded in 1975 with a cotton spinning mill in Purwakarta, Indonesia, PT Indo-Rama Synthetics has expanded its spun yarn business and diversified into manufacturing man-made fibers. Today, the Group exports to more than 70 countries across five continents. Its integrated plant specializes in spinning, knitting, dyeing and weaving, with a strong focus on 100% cotton, polyester, viscose and blends. The facility boasts an impressive installed capacity of around 428 000 spindles.