Boosting Spinning Mill Performance

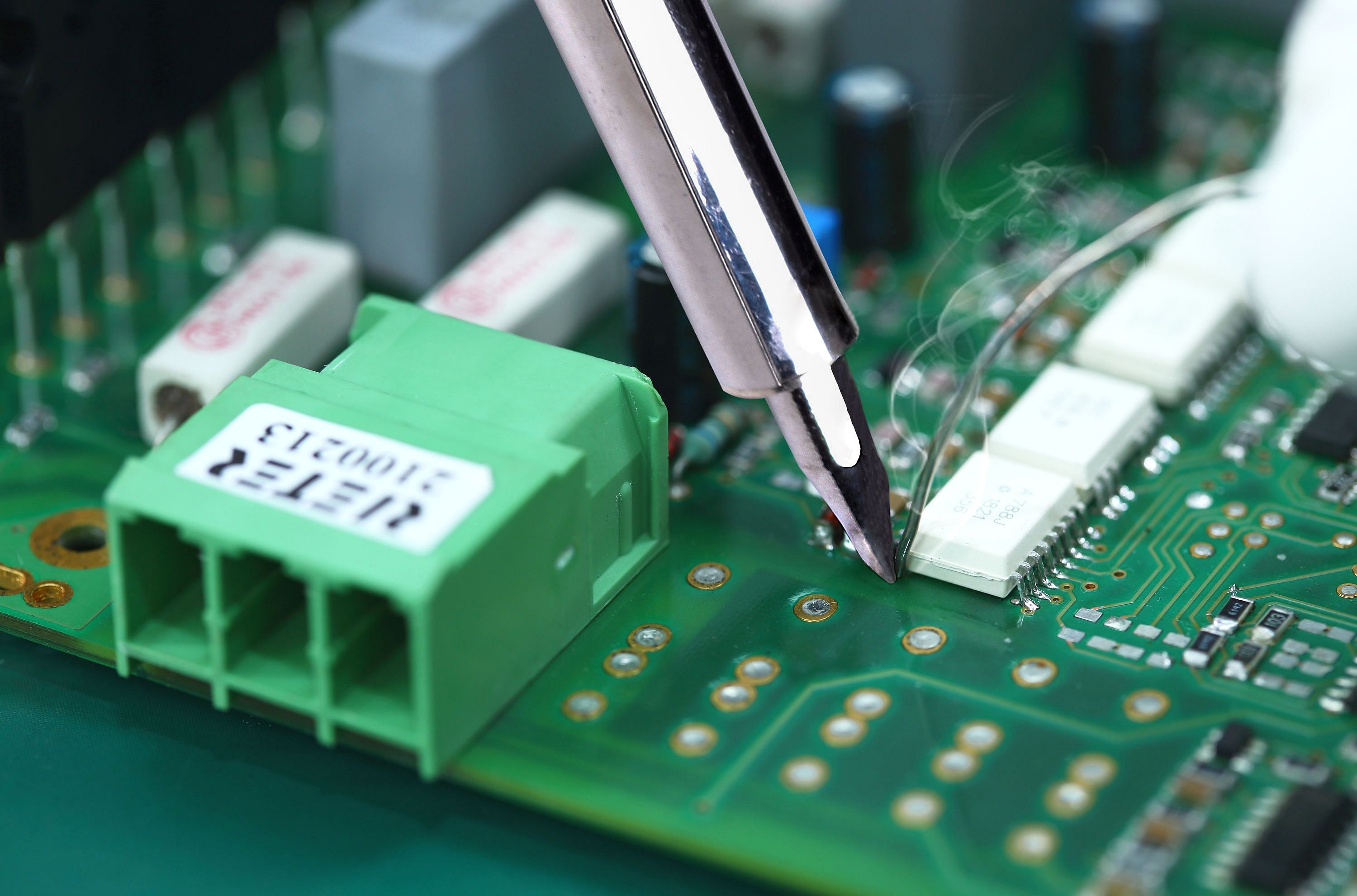

Spinning mills can boost productivity and extend the lifespan of their machines with Rieter’s tailored performance optimization solutions and premium-quality spare parts. These services ensure minimal downtime, maximum efficiency, and long-lasting reliability for all equipment.

Rieter's comprehensive after-sales portfolio covers every stage of the spinning process – from bale opening to end spinning to winding.