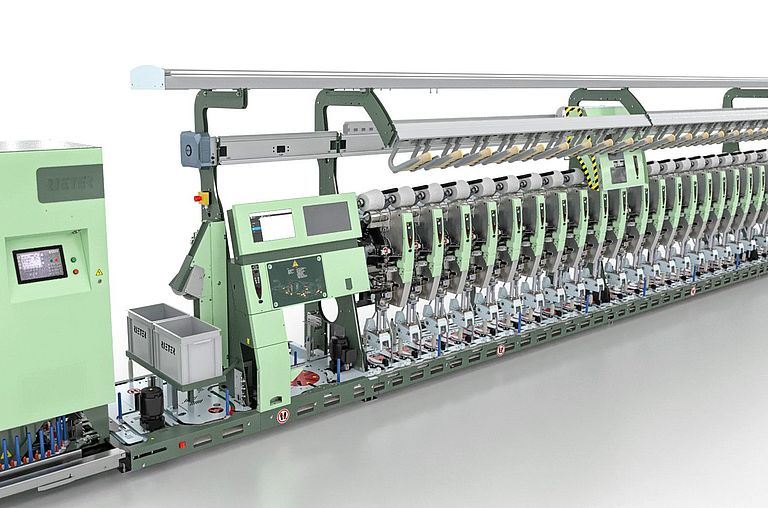

Introducing Autoconer X6

The Autoconer X6 stands for efficiency, quality and flexibility. With the lowest energy consumption, it sets standards in package winding. Customized automation, and the intelligent material flow with RFID technology makes the Autoconer X6 most suitable for modern spinning mills. The new Cop exchanger enables now again more flexible automation.

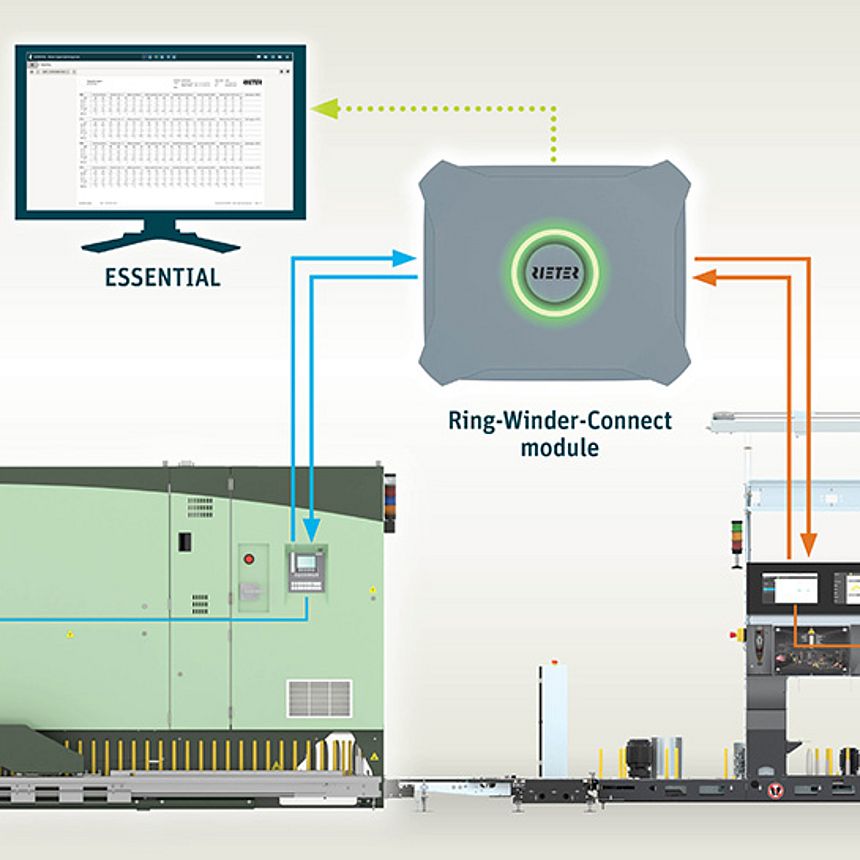

Real-time data analysis with the Rieter Ring-Winder-Connect ensures process reliability, better system integration and consistent quality. A compact, ergonomic design maximizes operator comfort. The Autoconer X6 produces highest package quality, both for commodity and high-end applications, while the open prism technology guarantees excellent splice quality.