Product details

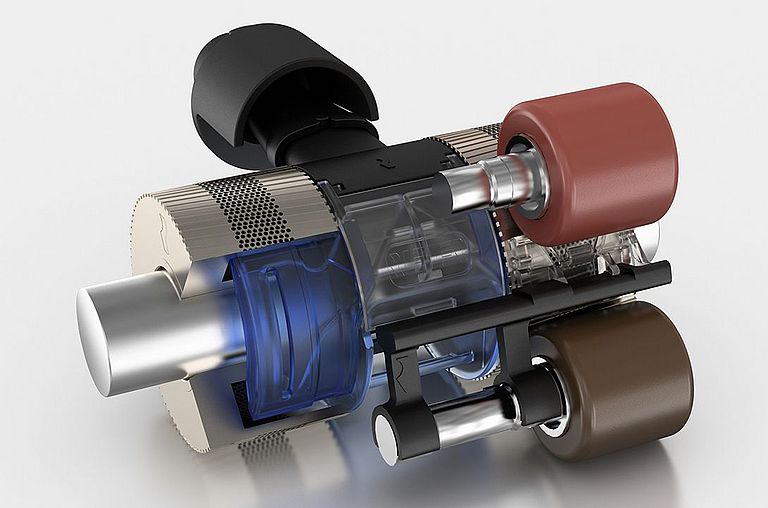

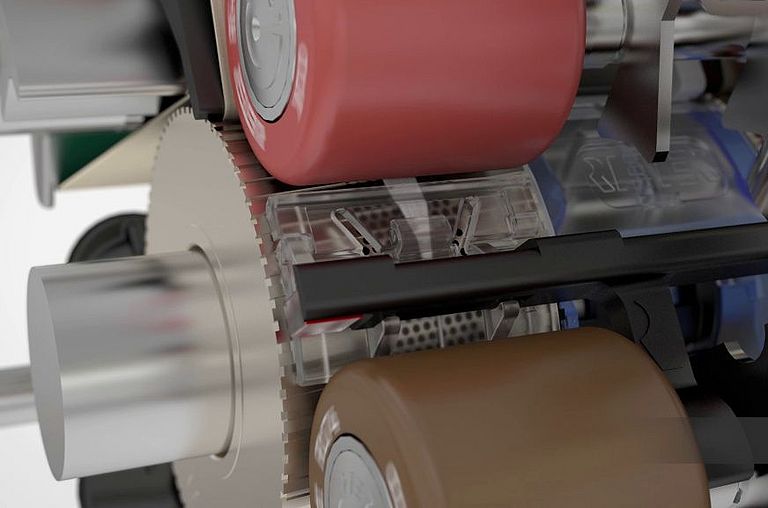

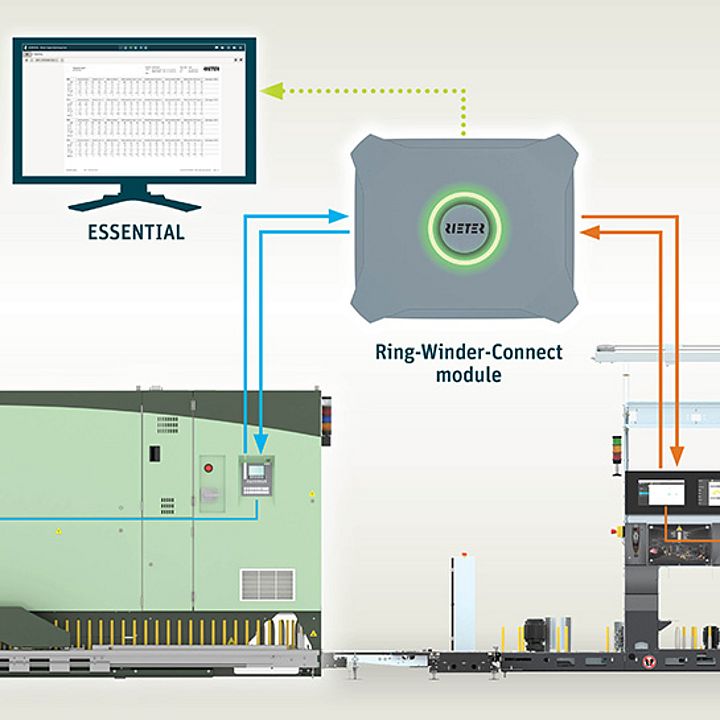

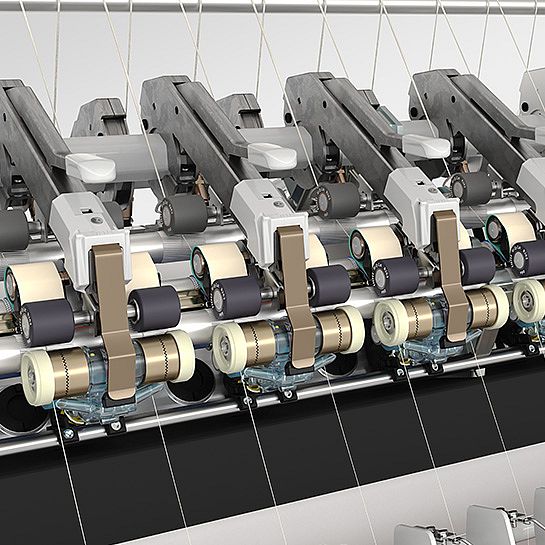

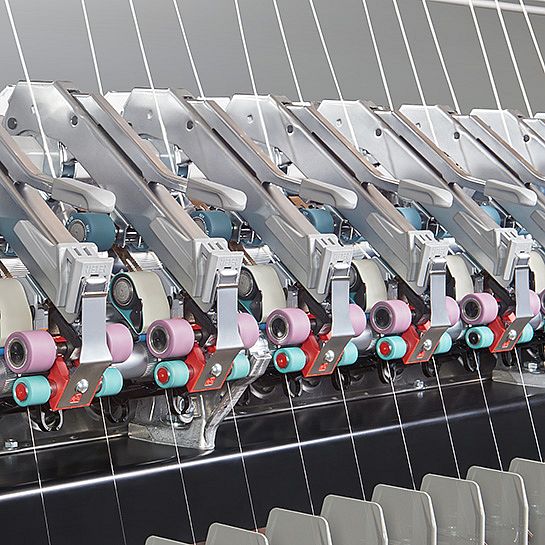

The compact-spinning machine K 47 with semi-electronic drafting system meets all requirements for an economical yarn production. The K 47 produces compact yarns using a low amount of energy thanks to energy-efficient components. With highest spindle speeds up to 28 000 rpm the production is increased by 12%.