Product details

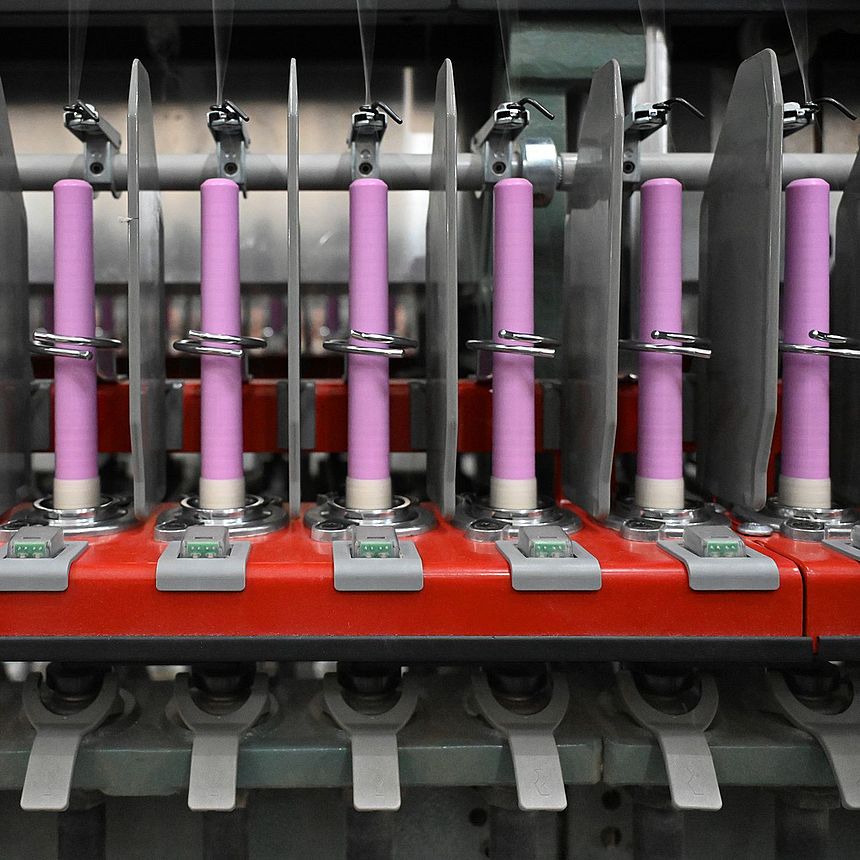

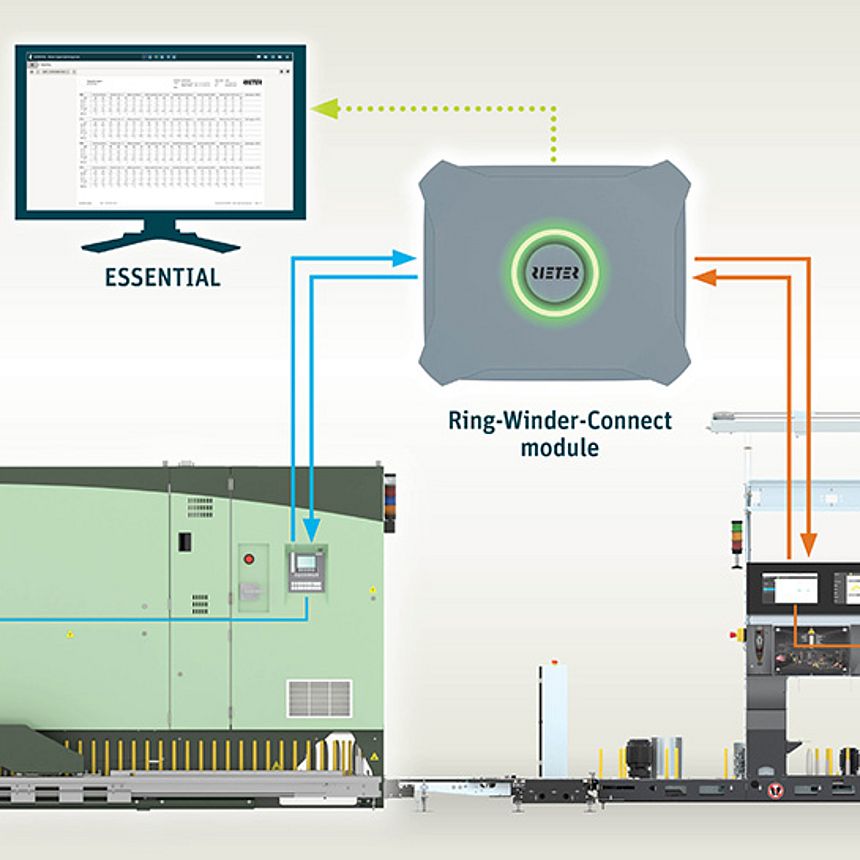

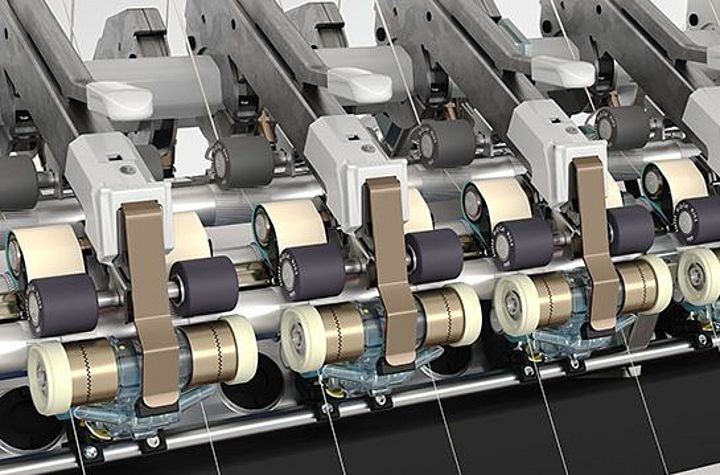

The compact-spinning machine K 48 produces compact and special yarns with spindle speeds of up to 28 000 rpm while minimizing energy consumption. With a 25% faster doffing system, optimized cop transport, and the new short balloon setting, production time is significantly increased. The highly wear-resistant compacting unit is the basis for quality and efficiency, and eliminates the need for an additional suction system. The piecing robot ROBOspin ensures performance with minimal personnel, further enhanced by the Individual Spindle Monitoring (ISM) system premium.