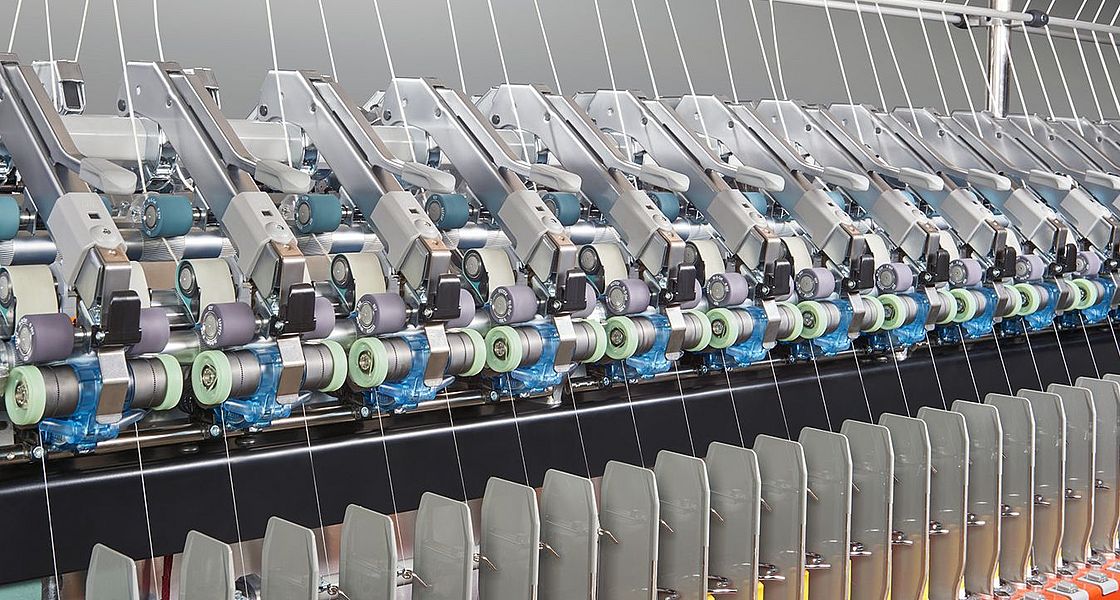

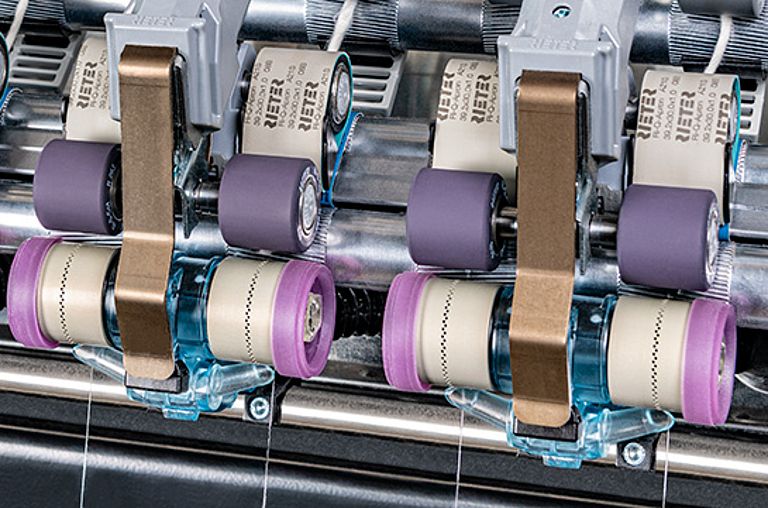

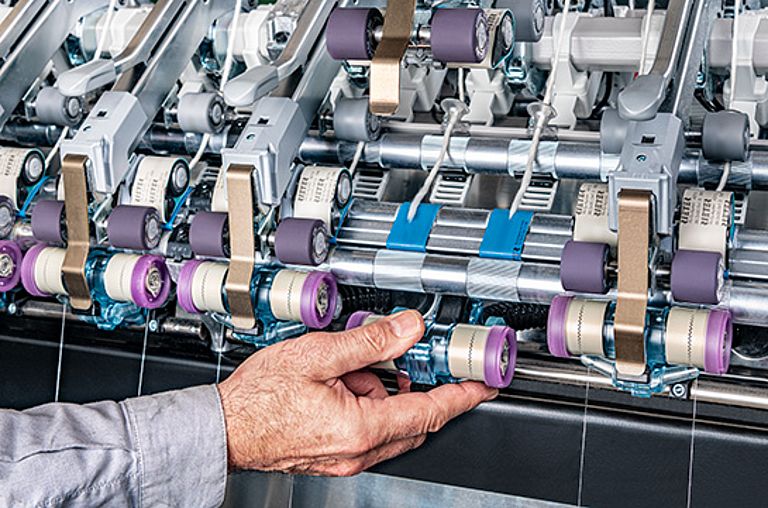

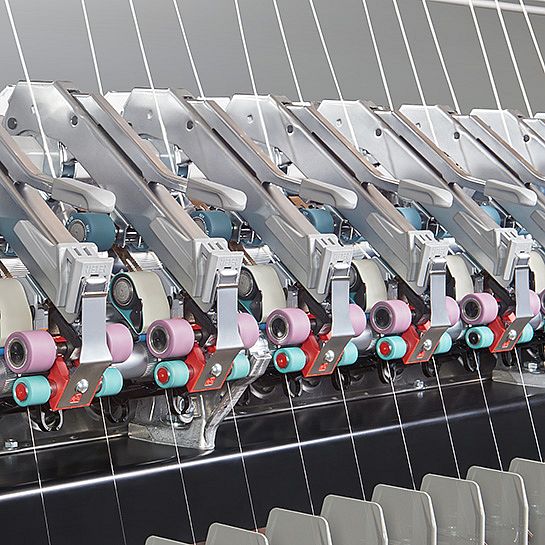

Product details

With easy installation and removal, the compacting device COMPACTdrum for the Rieter ring spinning machine allows for quick switches between ring yarn and compact yarn. COMPACTdrum adds a new dimension to reducing hairiness. Compact yarn produced in this way is highly sought-after in downstream processing. The device processes all raw materials and covers all yarn counts. With low energy requirements, very high productivity and long-life technology components, production costs are kept low.