Product details

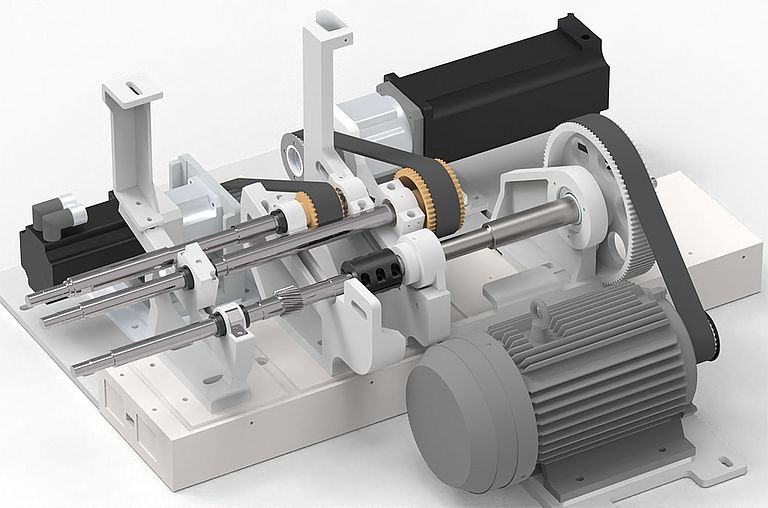

With up to 220 spinning positions and a gauge of 110 mm, the roving frame F 37 features a compact, space-saving design. High efficiency and low energy consumption are ensured by proven drive systems such as the sectional drive and toothed belt drive. Driving the rovings from below guarantees smooth operation and top-quality roving. A high level of automation is achieved through the automatic doffer, a transfer station, and the option to connect to a transport system.