Product details

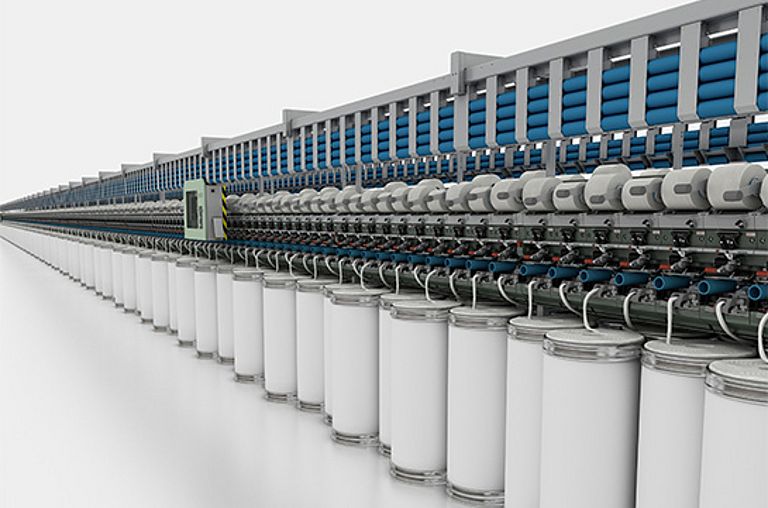

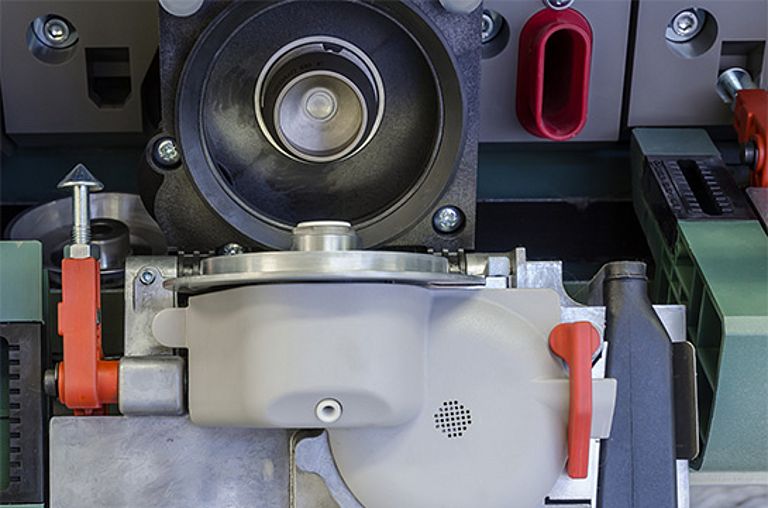

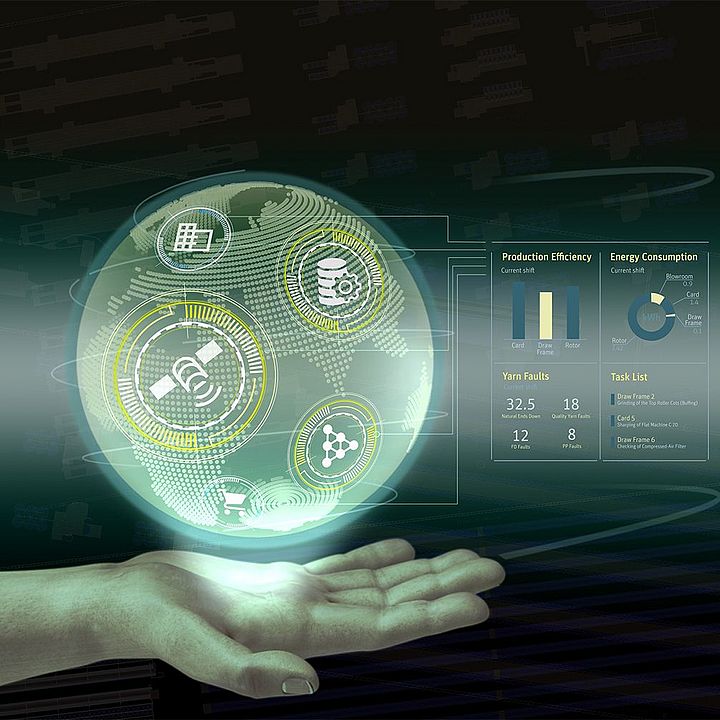

The rotor spinning machine R 37 has a new spinning box with adjustable trash extraction. This offers more flexibility when selecting the raw material. With up to 600 spinning positions, the R 37 ensures economical rotor spinning in the range Ne 3 to Ne 40 range.

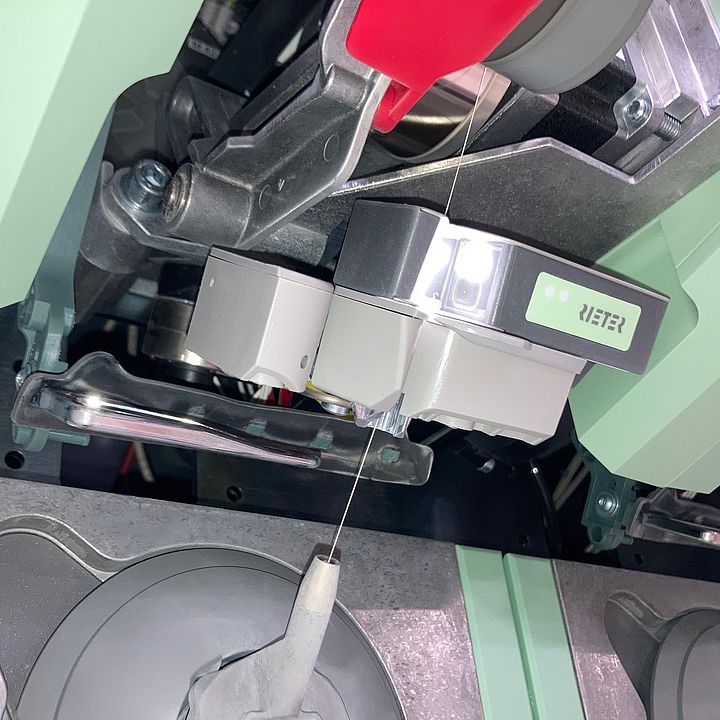

Low energy consumption and simple, time-saving handling by operating personnel minimize production costs. The innovative AMIspin and optional AMIspin-Pro technologies ensure superior piecing quality. Fully independent machine sides provide high flexibility. The robot ROBOdoff, which is available as an option, automates package change.