Introducing G 38

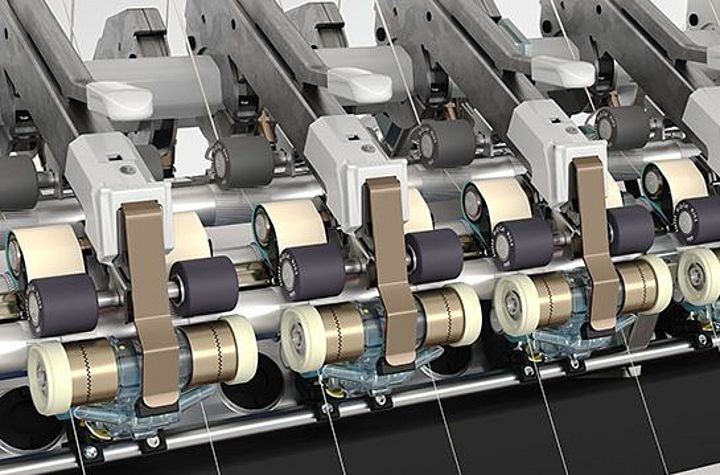

With spindle speeds up to 28 000 rpm the production is on the highest level. The machine consumes minimal energy thanks to energy-efficient components such as LENA 28 spindles, IE4 main motors and optimized suction systems. Customers benefit from the 25% faster doffing system. The new and faster cop transport system SERVOdisc needs less maintenance. The new version of the ring spinning machine G 38 is available either as fully or semi-electronic system on demand.